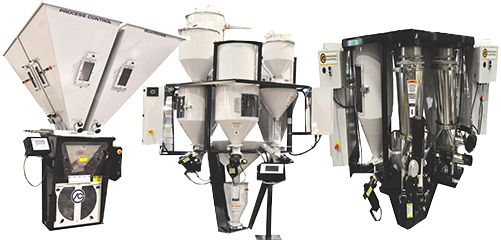

Process Control's Graviton® Gravimetric Extrusion Control Systems automates the control of any extrusion line -- coextrusion or mono extrusion - on the basis of weight.

A standard system has an HG Series Weigh Hopper mounted on each extruder to measure the extruder's weight throughput. The weigh hopper reports the measurement to the EXB2 central computer, which controls the extruder drive and/or takeoff device drive. Alternatively, Process Control X Series and Guardian® blenders can monitor extruder throughput and control the extruder drive and take-off device. In both cases, the B&R Drive Speed Module and the B&R Line Speed Control Module provide the interface for this communication.

The B&R Drive Speed Control circuit board is mounted on an L-bracket, that is designed for easy mounting in your existing drive cabinet. It can also be supplied in a stand-alone enclosure for remote mounting.

The B&R Line Speed Control Module consists of a circuit board on an L-bracket like the B&R Module. It also includes a pulse generator with encoder that accurately measures line speed for closed-loop control.

The B&R Line and B&R Drive cards receive digital signals from the Gravitrol® central computer and send analog speed reference signals to the drives. This signal can be either 0-10 VDC or 4-20 mA, and should be specified when the system is ordered. These boards are custom-designed, programmed, and tested in-house by Process Control engineers.

Sophisticated programming allows the system to ramp all drives synchronously. This enables the Gravitrol® system to make smooth transitions from the current line output to a new target output while maintaining product integrity.

The B&R Line and B&R Drive modules are designed for easy integration into a conventional extrusion control design with existing manual potentiometers or digital speed controls. The modules feature inputs for the manual speed control signals allow operators to use existing manual controls when required. The system is switched from manual to automatic (Gravitrol®) control through a single MANUAL/GRAVITROL® switch (available separately).

Gravitrol® also provides a computer-controlled manual mode that allows the operator to digitally set the speed of each extruder and/or line speed. This mode is normally used for line start-up.

Standard Features

- L-bracket design for cabinet mounting

- 0-10 VDC or 4-20 mA speed reference signal available

- Manual potentiometer inputs provided for fail-safe backup

Also Available

- Stand-alone enclosure for remote mounting

The Gravitrol® System: complete gravimetric extrusion control via drive speed control and line speed control (GRAVITROL® B&R Extruder Drive Speed Control Module Via B&R Line Speed Control Module card with pulse generator and encoder)