6875 Mimms Drive

Atlanta, GA 30340

Phone: 770.449.8810

Fax: 770.449.5445

Email: sales@process-control.com

Website: www.process-control.com

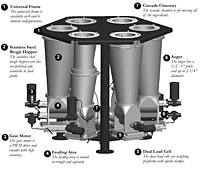

The XU Series 2 Gravimetric Continuous Powder Blenders offers unsurpassed blend accuracy and blend homogeneity in a wide range of configurations to meet the needs of any application by incorporating the PF Series powder feeders. It allows gravimetric blending of non-free-flowing powder materials with free-flowing powder and pellet materials at unprecedented metering and mixing accuracy.

The powder feeders allow rates as low as 0.2 PPH and as high as 6,000 PPH. Metering augers are available in full pitch or 1/2 pitch configurations with helix diameters from 1/4 inch to 2-1/4 inches.

The drive system of all blender components utilizes a motor drive with a brushless DC gearmotor and encoder for accurate motor speed feedback. This allows each of the individual feeders to maintain a constant RPM and weight throughput.

The weighing system is designed with DSP (digital signal processing) technology (patent pending) to filter out unwanted noise and vibration which can wreak havoc with any feeding system, especially at very low feed rates.

Incorporated into the electro-polished stainless steel design is a patented round-to-trough feeding area which provides more consistent mass flow for better metering accuracy. The feeder is designed with a steep wall, removable hopper which features a dust-tight band clamp for easy mounting of hopper extensions and quick disassembly for clean out. The bottom trough design is optimized to provide maximum material exposure to the auger.

The XU Series 2 Continuous Powder Blender is also available in food grade stainless steel.

The operator enters the desired blend recipe at the operator station. All ingredients are simultaneously metered in the correct blend ratios by augers from individual weighed PF Series powder feeders. The ingredients then flow through a cascade chamber which produces the best blend homogeneity.

Standard Features

Mechanical Features

Control Features

Options

Power

The XU Series: designed to produce precise, homogeneous powder blends by weight

| Items |

XU2C4 4 Elements XU-Series 2 Continuous Gravimetric Powder Blender |

XU2C6 6 Elements XU-Series 2 Continuous Gravimetric Powder Blender |

||

| Material of Construction | N/A Stainless Steel | |||

| Weighing System Resolution | N/A 1:1,000,000 | |||

| Voltage | N/A 115 V | |||

| Phase | N/A Single | |||

| Frequency | N/A 60 Hz | |||

| Options | N/A FDA Stainless Steel Gravimetric Extrusion Control High Temperature Design Pellet/Regrind Element Steep-wall Surge Bins with Knife Gates | |||

|

|

||||