-

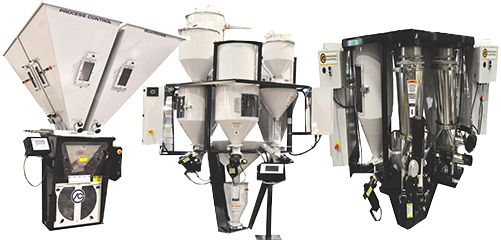

Gravimetric Continuous Blenders

gravimetric-continuous-blenders

-

Gravimetric Blending Brochure

Exceptional resin blending equipment via weigh scale type batch blenders and gravimetric continuous blender equipment. The level of accuracy delivered by PCC blending equipment saves you significant money over time, especially in the areas of color pellets and other high priced additives.

-

Continuous Blender Upgrades

Upgrades are available for Continuous Gravimetric Blenders. Please fill out the following pdf form (located to the right under "Downloads") and send it to sales@process-control.com for more information.

-

X Series 2 Gravimetric Continuous Blenders

The X Series 2 Gravimetric Continuous Blender offers unsurpassed blend accuracy and blend homogeneity in a wide range of configurations to meet the needs of any application. For extruder throat-mounted applications, the X Series 2 Blender comes equipped with an integral down-comer to preserve the blended material all the way to the extruder without demixing. For mezzanine or off-line mounting, the blender does not include the down-comer and is designed to work with a number of different options for storing the blended material prior to its use.

The operator enters the desired blend recipe at the operator station. All ingredients are simultaneously metered in the correct blend ratios by inclined augers from individual weighed material hoppers. The ingredients flow through a cascade chamber which produces the best blend homogeneity.

Mechanical Features- Individual weighed ingredient hoppers with easy-to-use drains

- Interchangeable metering units with quick disconnect

- Brushless DC gear motors with closed-loop control for precise ingredient measuring

- Integral loading platform for mounting vacuum receivers

- Designed for easy cleanout and quick changeover

- Mild steel construction

Control Features

- Blender monitors weight loss of each ingredient hopper for precise control of blend ratios

- Weighing system resolution is 1:1,000,000 for maximum accuracy

- Color touchscreen display for easy viewing of inventory performance data

- Storage for 400 blend recipes in battery-backed memory

- Multiple alarm levels with visual display and contact closures

Options

- Gravimetric Extrusion Control

- Steep-wall hoppers for regrind and other sluggish materials

- High temperature design

The X Series 2: designed to produce precise, homogeneous blends by weight

-

XU Series 2 Gravimetric Continuous Powder Blenders

The XU Series 2 Gravimetric Continuous Powder Blenders offers unsurpassed blend accuracy and blend homogeneity in a wide range of configurations to meet the needs of any application by incorporating the PF Series powder feeders. It allows gravimetric blending of non-free-flowing powder materials with free-flowing powder and pellet materials at unprecedented metering and mixing accuracy.

The powder feeders allow rates as low as 0.2 PPH and as high as 6,000 PPH. Metering augers are available in full pitch or 1/2 pitch configurations with helix diameters from 1/4 inch to 2-1/4 inches.

The drive system of all blender components utilizes a motor drive with a brushless DC gearmotor and encoder for accurate motor speed feedback. This allows each of the individual feeders to maintain a constant RPM and weight throughput.

The weighing system is designed with DSP (digital signal processing) technology (patent pending) to filter out unwanted noise and vibration which can wreak havoc with any feeding system, especially at very low feed rates.

Incorporated into the electro-polished stainless steel design is a patented round-to-trough feeding area which provides more consistent mass flow for better metering accuracy. The feeder is designed with a steep wall, removable hopper which features a dust-tight band clamp for easy mounting of hopper extensions and quick disassembly for clean out. The bottom trough design is optimized to provide maximum material exposure to the auger.

The XU Series 2 Continuous Powder Blender is also available in food grade stainless steel.

The operator enters the desired blend recipe at the operator station. All ingredients are simultaneously metered in the correct blend ratios by augers from individual weighed PF Series powder feeders. The ingredients then flow through a cascade chamber which produces the best blend homogeneity.

Standard Features- All mechanical components are disassembled from the drive end, without the uses of tools.

- Communication protocols supported include: EtherNet/IP, Allen Bradley [dh+], CCM, Siemens, Modbus TCP and Modbus/Extended, as well as proprietary EPCC and ASCII

- 4 or 6 element frames for mounting a variety of feeder options

Mechanical Features

- Individual weighed ingredient hoppers with easy-to-use drains

- Interchangeable metering units with quick disconnect

- Brushless DC gearmotors with drive control and closed-loop speed regulation

- Integral loading platform for mounting surge bins/vacuum receivers

- Designed for easy cleanout and quick changeover, no tools required

- Stainless steel construction, food grade optional

- Standard 4 and 6 element universal frames

Control Features

- Blender monitors weight loss of each ingredient hopper for precise control of blend ratios

- Weighing system resolution is 1:1,000,000 for maximum accuracy

- Color touch screen dispaly for easy viewing of inventory and performance data

- Storage for 400 blend recipes in battery-backed memory

- Multiple alarm levels with visual display and contact closures

Options

- Pellet/Regrind element

- Gravimetric Extrusion Control

- Steep-wall surge bins with knife gates for feeder loading

- High temperature design

- FDA stainless steel

Power

- 115V/1PH/60Hz or 230V/1Ph/50Hz

The XU Series: designed to produce precise, homogeneous powder blends by weight

-

VNC Viewer

The VNC Viewer provides a central control point for an unlimited number of touch screen supplied PCC blenders.

• 1.2 GHZ Dual-Core Processor

• Remote viewing for one or multiple controllers at a time

• 12.1" color TFT touch screen with 1280x800 widescreen resolution

• 512MB RAM memory

• DIN rail power supply

• Preloaded with embedded Linux

• Preloaded with VNC software for connection to blender

• Ethernet port for connection to blender

• Two USB ports for external keyboard and memory card

-

PCC Process Manager

SCADA process visualization software package, with the following features:

- For monitoring and controlling (1) PCC Continuous Blender, (1) PCC Batch Blender, or (1) PCC Gravitrol weigh hopper (w/ B&R Touchscreen, or Mini-Op equipped with Ethernet capability).

- includes one runtime version of Siemens WinCC software with SQL server, one license (for one computer only)

- Functions include real time blender operations (both monitor and control), material usage, historical trending, and alarm logging/notifications, all from one centralized location.

- Inventory trends and summary reporting can be exported to any spreadsheet program, such as Excel.

- Operator and Supervisory levels, with multiple security settings available.

- Virtually limitless expansion of the SCADA system to additional PCC and non-PCC equipment, by PCC. This expansion will be quoted, at a fixed price or an hourly rate, after receiving detailed specifications. Contact project engineering for more details.

Note: Customer is required to supply PC with Windows 7 OS or greater, with minimum hardware specifications