-

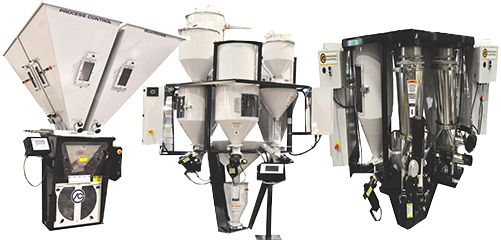

Gravimetric Batch Blenders

gravimetric-batch-blenders

-

Gravimetric Blending Brochure

Exceptional resin blending equipment via weigh scale type batch blenders and gravimetric continuous blender equipment. The level of accuracy delivered by PCC blending equipment saves you significant money over time, especially in the areas of color pellets and other high priced additives.

-

Autobatch and Guardian® Upgrades

Upgrades are available for the Autobatch and original Guardian® Blenders. Please fill out the following pdf form (located to the right under "Downloads") and send it to sales@process-control.com for more information.

-

Guardian® Series 2 Gravimetric 1.0 kg/2.2 lb Batch Blenders

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2. The blenders in the 1.0kg Guardian 2 family have been made with redesigned material hoppers to hold each of the ingredients. The 1.0kg can be supplied with up to six separate ingredient hoppers as standard.

Both of the designs come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials is dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%.

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features- • Each hopper has one 90° side and no transition sections for improved material flow.

- • Hopper access doors with redesigned latching system.

- • Detached weigh hopper discharge gate actuator for improved performance.

- • Removable cartridge style dispensing gates for ease of maintenance and clean out.

- • Optimized V-design metering gates for improved accuracy and dispensing range.

- • Color touch screen operator interface with new “off-the-shelf” control.

- • PCC Web® remote communication software

- • Gravitrol® extruder and linespeed control

- • Extension cable kit for remote mounting touch-screen operator control panel

- • Low level proximity sensors for material hoppers

- • Special electrical

- • Special Paint

- • Process Manager software

- • Self-Loading

- • Self-Cleaning

- • Up to 6 elements for 2.5kg

- • For higher throughputs, see specification sheets for 5kg, 12kg, 18kg and 25kg Guardian® Series 2 Gravimetric Blenders

-

Guardian® Series 2 Gravimetric 2.5 kg/5.5 lb Batch Blenders

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2. The blenders in the 2.5kg Guardian 2 family have been made with redesigned material hoppers to hold each of the ingredients. The 2.5kg can be supplied with up to six separate ingredient hoppers as standard.

Both of the designs come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials is dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%.

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features- • Each hopper has one 90° side and no transition sections for improved material flow.

- • Hopper access doors with redesigned latching system.

- • Detached weigh hopper discharge gate actuator for improved performance.

- • Removable cartridge style dispensing gates for ease of maintenance and clean out.

- • Optimized V-design metering gates for improved accuracy and dispensing range.

- • Color touch screen operator interface with new “off-the-shelf” control.

- • PCC Web® remote communication software

- • Gravitrol® extruder and linespeed control

- • Extension cable kit for remote mounting touch-screen operator control panel

- • Low level proximity sensors for material hoppers

- • Special electrical

- • Special Paint

- • Process Manager software

- • Self-Loading

- • Self-Cleaning

- • Up to 6 elements for 2.5kg

- • For higher throughputs, see specification sheets for 5kg, 12kg, 18kg and 25kg Guardian® Series 2 Gravimetric Blenders

-

Guardian® Series 2 Gravimetric 5 kg/11.1 lb Batch Blenders

The Guardian 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian 2.

The blenders in the 5kg Guardian 2 family have been designed with segmented material hoppers to hold each of the ingredients. The 5kg Guardian 2 can be supplied with up to eight separate ingredient hoppers as standard.

The outlet of each of the individual material hoppers is equipped with a fast acting V-gate valve. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogenous blend of any batch type blender.

Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blenders highest accuracy setting, each ingredient can be dispensed to an accuracy of ±0.02%

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections.

The Guardian 2 blenders have incorporated in the design a built in clean-out system. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned-out quickly and easily during product changeovers.

Standard Features- Integral loading platform for mounting vacuum receivers.

- Attached air hose & nozzle for cleaning.

- Support for a wide variety of communications protocols.

- Pulsing V-gate metering designed to accurately meter each ingredient in every batch.

- Advanced mechanical agitator in a "No Dead Zone" mixing chamber for a precise blend homogeneity.

- Integral drain chute provides for fast and thorough clean-out.

-

Guardian® Series 2 Gravimetric 12 kg/26.5 lb Batch Blenders

The Guardian 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian 2.

The blenders in the 12kg Guardian 2 family have been designed with segmented material hoppers to hold each of the ingredients. The 12kg Guardian 2 can be supplied with up to twelve separate ingredient hoppers as standard.

The outlet of each of the individual material hoppers is equipped with a fast acting V-gate valve. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogenous blend of any batch type blender.

Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blenders highest accuracy setting, each ingredient can be dispensed to an accuracy of ±0.02%

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections.

The Guardian 2 blenders have incorporated in the design a built in clean-out system. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned-out quickly and easily during product changeovers.

Standard Features- Integral loading platform for mounting vacuum receivers.

- Attached air hose & nozzle for cleaning.

- Support for a wide variety of communications protocols.

- Pulsing V-gate metering designed to accurately meter each ingredient in every batch.

- Advanced mechanical agitator in a "No Dead Zone" mixing chamber for a precise blend homogeneity.

- Integral drain chute provides for fast and thorough clean-out.

-

Guardian® Series 2 Gravimetric 18 kg/39.8 lb Batch Blenders

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2. The 18kg blender in the Guardian® Series 2 family has been made with redesigned material hoppers to hold each of the ingredients. The 18kg can be supplied with up to twelve separate ingredient hoppers as standard.

The outlet of each of the individual material hoppers is equipped with a fast acting V-gate valve. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogenous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features

- • Each hopper has one 90° side and no transition sections for improved material flow.

- • Hopper access doors with redesigned latching system.

- • Detached weigh hopper discharge gate actuator for improved performance.

- • Removable cartridge style dispensing gates for ease of maintenance and clean out.

- • Optimized V-design metering gates for improved accuracy and dispensing range.

- • Color touch screen operator interface with new “off-the-shelf” control.

Optional Features

- • PCC Web® remote communication software

- • Gravitrol® extruder and linespeed control

- • Extension cable kit for remote mounting touch-screen operator control panel

- • Low level proximity sensors for material hoppers

- • Special electrical

- • Special Paint

- • Blend Manager software

- • Self-Loading

- • Self-Cleaning

- • Up to 8 elements for 5kg

- • For higher throughputs, see specification sheets for 12kg, 18kg and 25kg Guardian® Series 2 Gravimetric Blenders

-

Guardian® Series 2 Gravimetric 25 kg/55.3 lb Batch Blenders

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2. The blenders in the 25kg Guardian® Series 2 family have been made with redesigned material hoppers to hold each of the ingredients. The 25kg can be supplied with up to twelve separate ingredient hoppers as standard.

Both of the designs come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%.

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features

- • Each hopper has one 90° side and no transition sections for improved material flow.

- • Hopper access doors with redesigned latching system.

- • Detached weigh hopper discharge gate actuator for improved performance.

- • Removable cartridge style dispensing gates for ease of maintenance and clean out.

- • Optimized V-design metering gates for improved accuracy and dispensing range.

- • Color touch screen operator interface with new “off-the-shelf” control.

- • PCC Web® remote communication software

- • Gravitrol® extruder and linespeed control

- • Extension cable kit for remote mounting touch-screen operator control panel

- • Low level proximity sensors for material hoppers

- • Special electrical

- • Special Paint

- • Blend Manager software

- • Self-Loading

- • Self-Cleaning

- • Up to 12 elements for 18kg and 25kg

- • For higher throughputs, see specification sheets for 1.25kg & 2.5kg, 5kg, and 12kg Guardian® Series 2 Gravimetric Blenders

-

VNC Viewer

The VNC Viewer provides a central control point for an unlimited number of touch screen supplied PCC blenders.

• 1.2 GHZ Dual-Core Processor

• Remote viewing for one or multiple controllers at a time

• 12.1" color TFT touch screen with 1280x800 widescreen resolution

• 512MB RAM memory

• DIN rail power supply

• Preloaded with embedded Linux

• Preloaded with VNC software for connection to blender

• Ethernet port for connection to blender

• Two USB ports for external keyboard and memory card

-

PCC Process Manager

SCADA process visualization software package, with the following features:

- For monitoring and controlling (1) PCC Continuous Blender, (1) PCC Batch Blender, or (1) PCC Gravitrol weigh hopper (w/ B&R Touchscreen, or Mini-Op equipped with Ethernet capability).

- includes one runtime version of Siemens WinCC software with SQL server, one license (for one computer only)

- Functions include real time blender operations (both monitor and control), material usage, historical trending, and alarm logging/notifications, all from one centralized location.

- Inventory trends and summary reporting can be exported to any spreadsheet program, such as Excel.

- Operator and Supervisory levels, with multiple security settings available.

- Virtually limitless expansion of the SCADA system to additional PCC and non-PCC equipment, by PCC. This expansion will be quoted, at a fixed price or an hourly rate, after receiving detailed specifications. Contact project engineering for more details.

Note: Customer is required to supply PC with Windows 7 OS or greater, with minimum hardware specifications