-

Extrusion Control Systems

extrusion-control-systems

-

Gravitrol Brochure

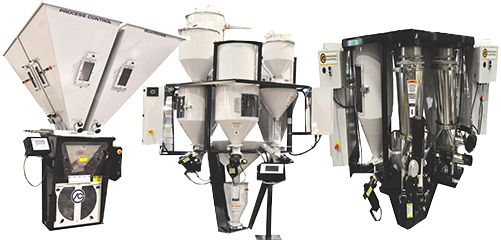

Gravitrol® extrusion control offers the benefits of improved product quality, reduced material usage, quicker startups and product changeovers, reduced scrap, and improved product repeatability.

At the same time, it reduces the operator’s workload by maintaining a constant output, regardless of screen pack or material variations.

The system uses Process Control’s proven Gravitrol® software to automate the control of the line and hold the extruder output to +/- 0.5% by weight. This tight control of output means that product can be made consistently within tolerance at the lowest possible cost, thereby saving thousands of dollars in resin.

-

Gravitrol Upgrades

Process Control offers a new selection of upgrades for Gravitrol, including a color touch screen controller, PLC based extruder line speed control, and a DSP weigh module upgrade kit, that will improve your system’s performance and longevity. These upgrades not only add years to your Gravitrol’s life, but can actually improve your accuracy as well. Additionally, the upgrades offer a way to simplify the process and postpone future replacement, making operation easier and saving you money all at once. Your older Gravitrol systems controls, drive modules, and weigh module chips are facing the threat of becoming obsolete; ensure that will not happen by upgrading today.

-

EXB2-Series GRAVITROL® Operator Stations

Process Control's Gravitrol® Gravimetric Extrusion Control Systems automate the control of any extrusion line - coextrusion or mono extrusion - on the basis of weight. The EXB2 Central Computer/ Operator Station is the key component of a complete Gravitrol® system.

A standard system has an HG Series Weigh Hopper mounted on each extruder to measure the weight throughput. The weigh hopper reports the measurements to the EXB2 central computer, which controls the extruder drives via B&R Drive Speed Modules. A B&R Line Speed Control Module can be added to control the take-off device for control of line yield (weight per length).

In coextrusion applications with Process Control X Series blenders, the EXB2 central computer communicates with the blenders' computers for integrated control.

The EXB2 communicates over a high-speed serial interface. Based on the weight readings from the weigh hoppers, the EXB2 periodically adjusts the speed of each extruder through the Drive Control Module (one per extruder).

The EXB2 Series is also the primary operator station for recipe entry, line operation and monitoring. The EXB2 contains an integrated membrane switch keypad for command/ data entry and an easy-to-read display. Alarm functions have been designed for maximum flexibility with three severity levels. Each level contains a separate LED indicator and contact closures that can be connected to any desired device. Security features include a key switch to prevent unauthorized access to system parameters and recipes.

The EXB2 Series also features remote interface capabilities that allow the Gravitrol® system to be integrated with a complete plant supervisory control system. Connectivity with yor protocals: Modbus RTU and Modbus IP, Allen Bradley E/IP CIP, and Profibus DP, Profinet. Through these remote interfaces, the Gravitrol® system can be controlled and monitored from a central location.

The EXB2 Central Computer/ Operator Interface, as part of a complete Gravitrol® system, offers flexibility and ease-of-use with the best possible gravimetric control.

Standard Features- Membrane switch keypad

- Vacuum fluorescent display status LED's

- Sophisticated 32-bit microcomputer

- Quick installation on new or existing line

- Security key for restricted access

- Stand-alone enclosure

- Mono extrusion control

Options

- Coextrusion control

- Gravitrol® B&R Drive Speed Control Modules

- Gravitrol® B&R Line Speed Control Module

- Interface to layflat controls

- Special electricals

- Profibus DP interface

The Gravitrol® System: complete gravimetric extrusion control (EXB2-Series GRAVITROL® Operator Station is the interface panel of the EXB2 Series Central Computer/Operator Station)

-

HGB-Series GRAVITROL® Weigh Hoppers

Designed for use as part of the Gravitrol® system, the HGB Series Weigh Hopper incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost.

The Gravitrol® system gives you total control over your mono-extrusion or coextrusion processes. The system can be configured to control extruder rate by weight; layer percentages by weight; weight of extrudate by length; average thickness; and pipe or tube diameter.

The HGB Series Weigh Hopper is a central part of this system because it precisely monitors the amount of material consumed by the extruder. In effect, the extruder becomes a gravimetric metering device.

PCC's HGB mounts directly on the throat of your extruder, requiring no additional support. Standard hopper sizes control an extruder throughput at rates from 10 to 10,000 PPH. Higher-rate hoppers are available on special order.

The HGB Series' clear polycarbonate inspection/clean out door or sight glass allows visual inspection of hopper contents.

Each hopper has a PCC-designed and built Weigh Module which connects to the load cell and precisely measures the extruder's material consumption. This information is digitized on the hopper for fast, error-free and noise-immune communications with the central Gravitrol® computer. Four-point overload protection on the hopper protects the weighing system from damage due to accidental contact.

Standard Features

•Integral loader support platform

•Clear polycarbonate inspection/cleanout door (on 2.3 cu. ft. models and larger)

•Inspection sightglass on 0.3 cu. ft. and 0.6 cu. ft. models

•Butterfly drain valve (on 2.3 cu. ft. models and larger)

•High-resolution DSP weighing system

•Integrates with a complete Gravitrol® extrusion control system for precise, consistent throughput control

•Mild steel construction

Options

•High temperature design

•Stainless steel construction

•Special electricals

•Positive shut-off knife-gate or swing-gate valve for gravity loading material from above

The HGB Series: the precise weigh hopper component of an integrated Gravitrol® system -

HG-Series 2 GRAVITROL® Weigh Hoppers

Designed for use as part of the Gravitrol® system, the HG Series 2 Weigh Hopper incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost.

The Gravitrol® system gives you total control over your monoextrusion or coextrusion processes. The system can be configured to control extruder rate by weight; layer percentages by weight; weight of extrudate by length; average thickness; and pipe or tube diameter.

The HG Series 2 Weigh Hopper is a central part of this system because it precisely monitors the amount of material consumed by the extruder. In effect, the extruder becomes a gravimetric metering device.

PCC’s HG2 mounts directly on the throat of your extruder, requiring no additional support. Standard hopper sizes control an extruder throughput at rates from 10 to 10,000 PPH. Higher-rate hoppers are available on special order.

The HG Series 2’s clear poly carbonate inspection/clean out door or sight glass allows visual inspection of hopper contents.

Each hopper is equipped with a touch screen PLC which connects to the load cell and precisely measures the extruder’s material consumption. This information is digitized on the hopper for fast, error-free and noise-immune communications with the central Gravitrol® computer. Four-point overload protection on the hopper protects the weighing system from damage due to accidental contact.

Standard Features- Integral loader support platform

- Clear polycarbonate inspection/cleanout door (on 2.3 cu. ft. models and larger)

- Inspection sightglass (on 0.3 cu. ft. and 0.6 cu. ft. models

- Butterfly drain valve (on 2.3 cu. ft. models and larger)

- Color touch screen control

- Integrates with a complete Gravitrol® extrusion control system for precise, consistent throughput control

- Mild steel construction

- Integral blender support for 2.5kg & 5kg Guardian(r) Series 2

- High temperature design

- Stainless steel construction

- Special electricals

- Positive shut-off knife-gate or swing-gate valve for gravity loading material from above

- Integral extruder and line speed motor/control

-

B&R-Series GRAVITROL® Extruder Drive Speed Control Module

Process Control's Graviton® Gravimetric Extrusion Control Systems automates the control of any extrusion line -- coextrusion or mono extrusion - on the basis of weight.

A standard system has an HG Series Weigh Hopper mounted on each extruder to measure the extruder's weight throughput. The weigh hopper reports the measurement to the EXB2 central computer, which controls the extruder drive and/or takeoff device drive. Alternatively, Process Control X Series and Guardian® blenders can monitor extruder throughput and control the extruder drive and take-off device. In both cases, the B&R Drive Speed Module and the B&R Line Speed Control Module provide the interface for this communication.

The B&R Drive Speed Control circuit board is mounted on an L-bracket, that is designed for easy mounting in your existing drive cabinet. It can also be supplied in a stand-alone enclosure for remote mounting.

The B&R Line Speed Control Module consists of a circuit board on an L-bracket like the B&R Module. It also includes a pulse generator with encoder that accurately measures line speed for closed-loop control.

The B&R Line and B&R Drive cards receive digital signals from the Gravitrol® central computer and send analog speed reference signals to the drives. This signal can be either 0-10 VDC or 4-20 mA, and should be specified when the system is ordered. These boards are custom-designed, programmed, and tested in-house by Process Control engineers.

Sophisticated programming allows the system to ramp all drives synchronously. This enables the Gravitrol® system to make smooth transitions from the current line output to a new target output while maintaining product integrity.

The B&R Line and B&R Drive modules are designed for easy integration into a conventional extrusion control design with existing manual potentiometers or digital speed controls. The modules feature inputs for the manual speed control signals allow operators to use existing manual controls when required. The system is switched from manual to automatic (Gravitrol®) control through a single MANUAL/GRAVITROL® switch (available separately).

Gravitrol® also provides a computer-controlled manual mode that allows the operator to digitally set the speed of each extruder and/or line speed. This mode is normally used for line start-up.

Standard Features- L-bracket design for cabinet mounting

- 0-10 VDC or 4-20 mA speed reference signal available

- Manual potentiometer inputs provided for fail-safe backup

Also Available

- Stand-alone enclosure for remote mounting

The Gravitrol® System: complete gravimetric extrusion control via drive speed control and line speed control (GRAVITROL® B&R Extruder Drive Speed Control Module Via B&R Line Speed Control Module card with pulse generator and encoder)

-

Gravimetric Extrusion Control for X-Series Blenders

PROCESS CONTROL "X" Series blenders can be equipped with extrusion control software to allow the blender to control the extruder and line speed on mono extrusion lines for consistent output by weight. The only additional hardware needed is an B&R extruder drive control module and, if line speed is to be controlled, an B&R line speed control module.

Gravitrol® extrusion control offers the benefits of improved product quality, reduced material usage, quicker startups and product changeovers, reduced scrap, and improved product repeatability. At the same time, it reduces the operator's workload by maintaining a consistent output, regardless of screen pack or material variations.

The system uses Process Control's proven Gravitrol® software to automate the control of the line and hold the extruder output to ±0.5% by weight. This tight control of output means that product can be made consistently within tolerance at the lowest possible cost.

Process Control "X" Series blenders monitor the extruder usage in order to follow the extruder rate and insure a consistent supply of material. In an extrusion control system, this extruder rate is used to adjust the screw speed by minute amounts to hold the overall throughput to the value entered in the blender operator station.

Because the blender already has a powerful computer and equipment necessary to measure the extruder rate, adding extrusion control on a mono extrusion line with a Process Control "X" Series blender is a very cost-effective addition. This feature can be easily retrofitted to existing installations with "X" Series or "B" Series blenders.

"X" Series blenders can also be easily integrated into coextrusion applications with extrusion control for controlling product layer ratios and total line throughput. On coextrusion applications the blender computer reports to a master B&R central Gravitrol® computer, which also receives weight throughput reading from HG Weigh Hoppers mounted on single-component extruders.

Standard Features- B&R Color Touch Screen

- Quick installation on new or existing lines

- 0-10 VDC or 4-20 mA analog drive control signals

- Gravitrol® B&R Drive Speed Control Module

- Gravitrol® B&R Line Speed Control Module

- Special Electricals

-

Process Manager

Integration by PCC means no third party integrators necessary.

Complete SCADA/DCS solutions from scratch OR add on to your exsisting solutions.

Monitor fully integrated systems from a centralized location.

Connectivity with your protocals: Modbus RTU and Modbus IP,

Allen-Bradley E/IP and CIP, Profibus DP, Profinet