HG-Series 2 GRAVITROL® Weigh Hoppers

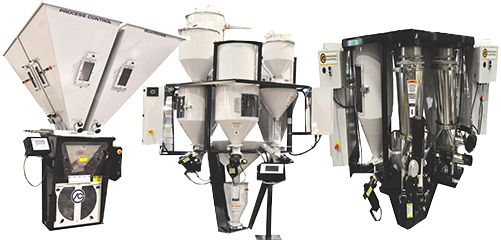

Extrusion Control Systems

Designed for use as part of the Gravitrol® system, the HG Series 2 Weigh Hopper incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost.

The Gravitrol® system gives you total control over your monoextrusion or coextrusion processes. The system can be configured to control extruder rate by weight; layer percentages by weight; weight of extrudate by length; average thickness; and pipe or tube diameter.

The HG Series 2 Weigh Hopper is a central part of this system because it precisely monitors the amount of material consumed by the extruder. In effect, the extruder becomes a gravimetric metering device.

PCC’s HG2 mounts directly on the throat of your extruder, requiring no additional support. Standard hopper sizes control an extruder throughput at rates from 10 to 10,000 PPH. Higher-rate hoppers are available on special order.

The HG Series 2’s clear poly carbonate inspection/clean out door or sight glass allows visual inspection of hopper contents.

Each hopper is equipped with a touch screen PLC which connects to the load cell and precisely measures the extruder’s material consumption. This information is digitized on the hopper for fast, error-free and noise-immune communications with the central Gravitrol® computer. Four-point overload protection on the hopper protects the weighing system from damage due to accidental contact.

Standard Features

The Gravitrol® system gives you total control over your monoextrusion or coextrusion processes. The system can be configured to control extruder rate by weight; layer percentages by weight; weight of extrudate by length; average thickness; and pipe or tube diameter.

The HG Series 2 Weigh Hopper is a central part of this system because it precisely monitors the amount of material consumed by the extruder. In effect, the extruder becomes a gravimetric metering device.

PCC’s HG2 mounts directly on the throat of your extruder, requiring no additional support. Standard hopper sizes control an extruder throughput at rates from 10 to 10,000 PPH. Higher-rate hoppers are available on special order.

The HG Series 2’s clear poly carbonate inspection/clean out door or sight glass allows visual inspection of hopper contents.

Each hopper is equipped with a touch screen PLC which connects to the load cell and precisely measures the extruder’s material consumption. This information is digitized on the hopper for fast, error-free and noise-immune communications with the central Gravitrol® computer. Four-point overload protection on the hopper protects the weighing system from damage due to accidental contact.

Standard Features

- Integral loader support platform

- Clear polycarbonate inspection/cleanout door (on 2.3 cu. ft. models and larger)

- Inspection sightglass (on 0.3 cu. ft. and 0.6 cu. ft. models

- Butterfly drain valve (on 2.3 cu. ft. models and larger)

- Color touch screen control

- Integrates with a complete Gravitrol® extrusion control system for precise, consistent throughput control

- Mild steel construction

- Integral blender support for 2.5kg & 5kg Guardian(r) Series 2

- High temperature design

- Stainless steel construction

- Special electricals

- Positive shut-off knife-gate or swing-gate valve for gravity loading material from above

- Integral extruder and line speed motor/control

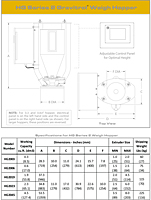

Item # |

Working Capacity |

Dimension A |

Dimension B |

Maximum Extruder Size |

Minimum Extruder Size |

Shipping Weight |

|---|---|---|---|---|---|---|

| HG2003 HG2003/Asset/HG2.png | Working Capacity N/A 0.3 ft³8.5 dm³ | Dimension A N/A 28.3 in719 mm | Dimension B N/A 10.0 in254 mm | Maximum Extruder Size N/A 2.0 in51 mm | Minimum Extruder Size N/A 1.0 in25 mm | Shipping Weight N/A 60 lb27 kg |

| HG2006 HG2006/Asset/HG2.png | Working Capacity N/A 0.6 ft³17.0 dm³ | Dimension A N/A 28.3 in719 mm | Dimension B N/A 10.0 in254 mm | Maximum Extruder Size N/A 2.5 in64 mm | Minimum Extruder Size N/A 1.5 in38 mm | Shipping Weight N/A 75 lb34 kg |

| HG2019 HG2019/Asset/HG2.png | Working Capacity N/A 1.9 ft³53.8 dm³ | Dimension A N/A 37.3 in946 mm | Dimension B N/A 11.0 in279 mm | Maximum Extruder Size N/A 4.5 in114 mm | Minimum Extruder Size N/A 2.0 in51 mm | Shipping Weight N/A 115 lb70 kg |

| HG2023 HG2023/Asset/HG2.png | Working Capacity N/A 2.3 ft³65.1 dm³ | Dimension A N/A 34.8 in883 mm | Dimension B N/A 11.0 in279 mm | Maximum Extruder Size N/A 6.0 in152 mm | Minimum Extruder Size N/A 2.5 in64 mm | Shipping Weight N/A 115 lb70 kg |

| HG2045 HG2045/Asset/HG2.png | Working Capacity N/A 4.5 ft³127.4 dm³ | Dimension A N/A 53.5 in1359 mm | Dimension B N/A 11.0 in279 mm | Maximum Extruder Size N/A 8.0 in203 mm | Minimum Extruder Size N/A 3.5 in89 mm | Shipping Weight N/A 255 lb116 kg |