6875 Mimms Drive

Atlanta, GA 30340

Phone: 770.449.8810

Fax: 770.449.5445

Email: sales@process-control.com

Website: www.process-control.com

Process Control specializes in equipment for bulk conveying of plastic materials. Our conveying equipment is designed to stand up to the demands of your application.

To prevent bottle-necking and ensure a continuous supply to the material's destination, Process Control engineers work with you to select the best equipment and integrate it into a reliable system capable of continuous operation and guaranteed performance.

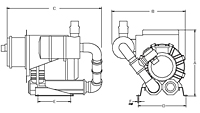

The VB Series from Process Control is designed for low to moderate rate conveying and quiet, low-maintenance performance. As part of an integrated material handling system, the VB Series can improve the efficiency of your plastics processing.

Standard Features

Options

For Your Material Handling Applications, PCC Also Offers:

The VB Series: designed for low to moderate rate conveying of pellets and regrinds

Item # |

Motor Power |

Tube Size |

Dimension A |

Shipping Weight |

|---|---|---|---|---|

| VBB | N/A 3 hp2.2 kW | N/A 2.0 in51 mm | N/A 23.1 in587 mm | N/A 100 lb45 kg |

| VBC | N/A 6.2 hp4.5 kW | N/A 2.0 in51 mm | N/A 20.0 in509 mm | N/A 150 lb54 kg |

| VBD | N/A 7.5 hp5.6 kW | N/A 2.5 in64 mm | N/A 23.8 in605 mm | N/A 200 lb91 kg |