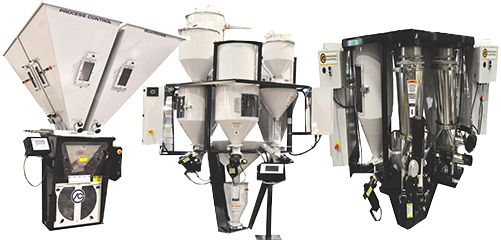

Process Control specializes in equipment for bulk conveying of plastic materials. Our conveying equipment is designed to stand up to the demands of your application.

To prevent bottle-necking and ensure a continuous supply to the material's destination, Process Control engineers work with you to select the best equipment and integrate it into a reliable system capable of continuous operation and guaranteed performance.

The VB Series from Process Control is designed for low to moderate rate conveying and quiet, low-maintenance performance. As part of an integrated material handling system, the VB Series can improve the efficiency of your plastics processing.

Standard Features

- 3, 6.2, and 7.5 HP available

- Quiet ring compressor design

- TEFC Motor (indoors only)

- Dual-stage intake filter

- Vacuum relief valve

- Power: 460V/3PH/60Hz

- Control Voltage: 24VDC or 115VAC

- Motor starter panel

Options

- Variable Speed Drive controlled

- Special Voltages

- Continuous Run Valve to Reduce Pump Cycling

For Your Material Handling Applications, PCC Also Offers:

- Central Vacuum Pumps - VE and VF Series

- Vacuum Receivers - RN Series for Pellets. RP Series for Regrinds and/or Powder Materials

- Sequencing Control Panels - Director Series

- Central Dust Collector - RDJ Series

- Interconnecting Tubing and Hardware

- Surge Bins and Silos

- Tilt Tables

- Railcar Unloading Systems

- Mechanical Installation

The VB Series: designed for low to moderate rate conveying of pellets and regrinds

Specifications

Motor Power |

N/A 6.2 hp4.5 kW |

Tube Size |

N/A 2.0 in51 mm |

Control Voltage (DC) |

N/A 24 V |

Control Voltage (AC) |

N/A 115 V |

Paint Type |

N/A Special |

Shipping Weight |

N/A 150 lb54 kg |