-

Material Handling

material-handling

-

MHS Brochure

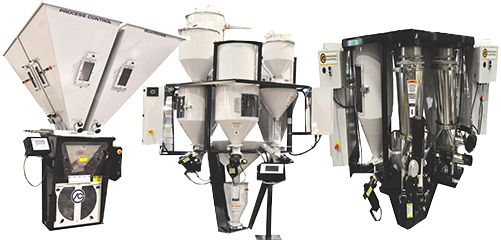

Complete In-Plant Conveying and Storage

Bulk storage and automatic conveying of raw materials in your plant reduces labor requirements

and improves overall operating efficiency. Process Control offers a complete line of

material handling systems from railcar unloading and bulk storage to vacuum and pressure

conveying systems for in-plant distribution and resin drying systems. Our Project Engineers

are experts in designing the best and most economical system to meet your needs.

Process Control’s material handling equipment is specially designed for bulk conveying of

plastic materials. Years of experience with plastic processors enable Process Control engineers

to properly size conveying equipment for reliable, cost-effective loading of gravimetric

or bulk systems. A complete line of equipment is available including pumps, receivers,

controllers, bulk storage silos, day bins and hardware necessary for railcar unloading and

integrated plant distribution systems. Compact, simple systems are available for lower

throughput applications.

-

VF-Series Vacuum Power Unit

Process Control's material handling equipment is specially designed for bulk conveying of plastic materials. Years of experience with plastic processors enable Process Control engineers to properly size conveying equipment for reliable, cost-effective loading of gravimetric or bulk systems. A complete line of equipment is available including pumps, receivers, controllers, bulk storage silos, day bins and hardware necessary for railcar unloading and integrated plant distribution systems. Compact, simple systems are available for lower throughput applications.

The VF Series is our most popular line of vacuum power units, offering dependable and economical performance for a wide variety of conveying rates, distances and materials. Typical applications include in-plant distribution systems and machine/blender loading. Each system is carefully sized using PCC's computer calculations to meet your conveying specifications.Standard Features

- 3 to 30 horsepower available

- Positive displacement blower

- Enclosed, V-belt drive

- Single element paper filter assembly

- T-frame TEFC motor (indoor or outdoor)

- Discharge silencer

- Vacuum relief valve and gauge

- Motor starter panel

Options

- Variable Speed Drive controlled

- Special voltages

- Continuous run valve to reduce pump cycling

- Sound-deadening enclosures

- Outdoor construction

The VF Series: designed for conveying of plastic materials (Both sound enclosed and non sound enclosed models)

-

VB-Series Vacuum Power Unit

Process Control specializes in equipment for bulk conveying of plastic materials. Our conveying equipment is designed to stand up to the demands of your application.

To prevent bottle-necking and ensure a continuous supply to the material's destination, Process Control engineers work with you to select the best equipment and integrate it into a reliable system capable of continuous operation and guaranteed performance.

The VB Series from Process Control is designed for low to moderate rate conveying and quiet, low-maintenance performance. As part of an integrated material handling system, the VB Series can improve the efficiency of your plastics processing.

Standard Features- 3, 6.2, and 7.5 HP available

- Quiet ring compressor design

- TEFC Motor (indoors only)

- Dual-stage intake filter

- Vacuum relief valve

- Power: 460V/3PH/60Hz

- Control Voltage: 24VDC or 115VAC

- Motor starter panel

Options

- Variable Speed Drive controlled

- Special Voltages

- Continuous Run Valve to Reduce Pump Cycling

For Your Material Handling Applications, PCC Also Offers:

- Central Vacuum Pumps - VE and VF Series

- Vacuum Receivers - RN Series for Pellets. RP Series for Regrinds and/or Powder Materials

- Sequencing Control Panels - Director Series

- Central Dust Collector - RDJ Series

- Interconnecting Tubing and Hardware

- Surge Bins and Silos

- Tilt Tables

- Railcar Unloading Systems

- Mechanical Installation

The VB Series: designed for low to moderate rate conveying of pellets and regrinds

-

Director™ Series Conveying System Sequencing Panel

Process Control offers a complete line of material handling equipment specifically designed for reliable conveying and distribution of plastic materials. The Director™ Series sequencing control panel is an easy-to-use touch screen panel that allows operators the ability to control and monitor all aspects of a central vacuum loading system. The sequencing panel controls the central vacuum pump, the vacuum receivers and can also control a central dust collector and a continuous run valve.

All information and operating controls of the Director™ are located on a touch screen interface. The touch screen interface allows the user to activate, adjust and monitor loading and system information on the panel.

Most features on the user interface are self-explanatory, but a HELP key is located on every screen to further assist with operational procedures.

The Director™ Series sequencing control panel uses the reliable Allen Bradley MicroLogix™ 1400 PLC to control the loading process. With an automatic fill time calculation, the Director™ can automatically determine and set the fill time for any or all stations, considerably reducing start-up time. System configurations can be specified to load from 4 to 30 stations using one or more pumps. Other configurations can also be defined based on the requirements of the system. The entire system has been intuitively mapped giving the user benefits in both technology and process control.

The easy-to-use Director™ Series will provide many years of trouble free service. With the best in touch screen technology and friendly operational mapping, the Director™ will assist you in controlling and monitoring all aspects of a central vacuum loading system.

Standard Features- Allen Bradley MicroLogix™ 1400 PLC with Ethernet port

- 6" monochrome touch screen

- Displays alarm conditions and maintains alarm log

- Automatic fill time calculation

- Status or progress monitor

Optional Features

- 10" Color touch screen

- Multiple pump, dust collector control

- Special controls and electricals

- Pump variable speed control for each station

- Remote panel

- Remote communication capability via Ethernet/IP, DeviceNet or DH485

The Director™ Series: automatic control of vacuum conveying systems

-

RN-Series Vacuum Receiver for Pellets

The RN Series Vacuum Receiver, from Process Control, is part of a complete vacuum conveying system for in-plant distribution or machine/blender loading. When coupled with a vacuum pump and sequencing panel (both priced separately), the RN Series provides automatic loading of pellet materials.

The RN Series Vacuum Receiver is designed to be mounted at any point where resin delivery is needed. As the station calls out for a load, a sequencing panel sends a signal to the RN to open its sequencing valve and pull vacuum on this receiver. The material is pulled from the connected source until the fill cycle is complete. Then, the material is dumped from the receiver immediately (by means of a flapper valve) or held for future use (by a positive shutoff valve).

A built-in screen prevents carry-over of pellet material back to the vacuum pump. For materials which have significant fines and dust, an optional dust collector should be purchased to reduce maintenance and protect the vacuum pump.

The RN Series Vacuum Receiver is low-maintenance: no valves come into contact with conveyed material and no tools are needed for pellet retaining screen changes.

Standard Specifications- Air operated sequencing valve in lid requires 80-100 psi of filtered, lubricated shop air for solenoid actuators and control cylinders. The total supply air required per cycle is 0.005 cu. ft.

- 24 VDC control voltage

- Load level proximity switch

- Flapper-type valve to create a positive seal

- Simple slide-out pellet screen with two side latches.

- Mild steel construction

- Check valve for common material line applications

- Swing-gate or knife-gate positive shut-off discharge valve

- 110VAC control voltage

- Stainless steel construction

- Director series sequencing control panel

- Central vacuum power unit

- Central dust collector

- High temperature design

-

RP-Series Vacuum Receiver for Dusty Material

The RP Series Vacuum Receiver from Process Control is part of a complete vacuum conveying system for in-plant distribution or machine/blender loading. When coupled with a vacuum pump and sequencing panel, the RP Series provides automatic loading of materials.

The RP's design accomplishes cleaning with conveying air. No plant compressed air is used for cleaning. The receiver's self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. At the start of the cycle, air is drawn backward through one set of filter bags, dislodging any fines and dropping them back into the hopper. After filling, the second set of filters is back flushed. Finally, both filters are opened; the resin is delivered to its destination.

The RP Series avoids carry-over of dust back to the vacuum power unit. The filter bags in the RP Series feature large filter areas to promote low, stable pressure drop.

The RP Series Vacuum Receiver is low-maintenance. No valves come into contact with conveyed material and no tools are needed for filter cleaning or changes.

Multiple station capability is engineered into the RP Series design, allowing use of vacuum valves. PCC's RP Series is easily retrofitted to conform to your existing standard vacuum system. An optional modular control box operates valves from the existing sequencing fill signal to minimize field wiring.

Standard Features- Air operated sequencing valve in lid requires 80-100 psi of filtered, lubricated shop air for solenoid actuators and control cylinders. The total supply air required per cycle is 0.01 cu. ft.

- Internal self-cleaning filter bags for granular or dusty materials

- 24 VDC control voltage

- Flapper-type discharge valve with magnetic switch

- Removable lid with V-band clamp

- Mild steel construction

- Check valve for common material line applications

- Swing-gate or knife-gate positive shut-off discharge valve

- 110VAC control voltage

- Stainless steel construction

- Load level proximity switch

- Pre-wired junction box to simplify installation

- High temperature design

-

LC-Series Compressed Air Loaders

The LC Series vacuum loader from Process Control is a space efficient, self-contained unit which uses compressed air to convey materials at rates up to 850 PPH. It can be used effectively in any application that calls for raw material delivery.

The LC Series loader is economically priced and comes equipped with all components needed to quickly load raw materials into any processing machine or storage bin. Each unit is shipped fully assembled and tested. The LC Series can be used to load pellets, regrinds, and granular type materials.

The LC Series assembly is comprised of a high efficiency cyclonic hopper mounted on a clear view tube with mounting flange, an air-flow amplifier, an exhaust air filter, and control box. Loading is controlled by a proximity sensor mounted in the view tube. All components are attached directly to the unit, making installation fast and simple. An aspirated pickup wand and 10 ft of PVC flex hose is included for pulling raw material from Gaylord boxes or storage bins.

The direct-mount design of the LC Series is ideal for machine-side loading applications and eliminates the need for bulky, machine-mounted surge hoppers. The LC Series loaders offer continuous, reliable operation with minimal required maintenance. Cleanout is quick, and fast material changes are easily accomplished without wasteful down-time for draining and cleaning common with larger surge hoppers.

Standard Features- Clear view material outlet tube

- Mounting flange

- Easily accessible, top-mounted air discharge filter

- Load level proximity sensor

- Aspirated pickup wand and 10 ft of PVC flex hose

- Air operated venturi requires 80 - 100 psi plant compressed air. Total supply air required varies based on model and throughput.

- Power: 115V/1PH/60Hz or 230V/1PH/50Hz

- Mild steel construction

- Custom mounting adapter

- Stainless steel construction

- Dual inlet for proportional loading of pellets and regrinds. Brings both material in simultaneously to eliminate layering. The percentages are set by adjusting the air pressure settings.

-

RD-Series Dust Collector

The operational design of the RD Dust Collector works to efficiently remove any fines acquired during a fill cycle. Its cleaning system is operated by the Sequencing Controller to properly back flush the bags. After ten consecutive receivers have filled, the RD automatically takes time out to clean filters. Cleaning also occurs at the end of any loading fill cycle. Various filter bags are available for anything from coarse to extremely fine dust. The filter bags can be easily replaced or cleaned as needed. Once the back flush cleaning system is done, dust is dropped into a bucket for easy removal.

The self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. Step 1 at the beginning of the loading cycle, the valve controlling filter area #1 is open to the atmosphere while a vacuum is drawn on filter area #2. This causes air to be drawn backward through filter area #1, dislodging any accumulated fines and dropping them back into the receiver hopper. After this short back flush phase, the second filter area is back flushed by opening it to the atmosphere while the vacuum continues to be drawn on the first filter area (Step 2). Finally, both filter areas are open to atmosphere and the dust is delivered to the bucket (Step 3).

As part of Process Control's Material Handling System, the RD Dust Collector is the ideal solution for dust removal on the vacuum line of a system. With the timed self-cleaning, it keeps the line free of any possible fines associated with pellets or regrind material with minimal operator intervention

Standard Features- Filter bags

- V Band Clamp

- Dual Solenoid Sequencing T (performs cleaning)

- Flapper Valve Material exit

- Built-in Stand

- Easily removable bucket for dust collection

- AC or DC solenoids

-

PT-Series Pneumatic Box Tilter

Process Control's PT Series Floor Level Box Tilter is an easy-to-use Gaylord container tilter which offers fork truck, pallet jack, or hand truck loading of bulk containers. Its rugged construction and reliable operating assemblies assure long lasting, dependable operation. By adjusting the PSIG on the air bag to a prescribed setting, a constant pressure slowly lifts the Gaylord automatically as it empties and becomes lighter. This action moves the material to the corner and allows the pick-up lance to completely empty the container. Most loose materials will empty completely. However, for difficult flowing materials, an optional vibration package is available. An adjustable wand holder is provided to facilitate easy attachment of a standard vacuum pick-up lance.

Standard Features- Capacity: 2,000 lbs maximum

- Base Dimensions: 71" x 52"

- Floor space requirement: 71" x 80"

- Floor level entry provides easy loading and unloading of containers

- Adjustable pick-up lance holder

- Tilts container to 45 degrees

- Tilt bucket drops flat on the floor

- Easy loading and unloading of containers

- Flexibility with entry from two different angles

- Smooth lifting with air bag device which is coupled with a pressure regulator and gauge

- Setting the PSIG allows tilter to lift with a constant pressure so material moves toward wand for complete cleanout

- Hand control

- Power system: air (40-100 psi required)

- Heavy-duty mild steel construction

- Vibrator for difficult flowing materials

- Casters

- Special Paint

-

HS-Series Surge Hoppers

The HS Series Surge Hoppers from Process Control are ideal for in-plant storage of both raw materials and finished product. They are available in a variety of sizes and capacities to maximize and conserve handling time, space, and energy. Standard capacities range from 30 cu. ft. to 290 cu. ft. and are available with hopper slopes of 45º or 60º depending on the flow characteristics of the material being stored. Custom designed bins with 70º hopper slopes can also be supplied for regrinds or difficult flowing materials.

The heavy duty design of the HS Series features welded carbon steel construction with formed angle iron legs and reinforcement bracing. The lid of the HS Series is designed for easy mounting of Process Control vacuum receivers or cyclones, and features a hinged cover for easy access. Other standard features include lifting lugs for easy placement of the bin in the plant, bolt down foot pads to securely anchor the bin to the floor, and high and low level view windows for quick visual inspection of the material level within the bin.

Process Control supplies a complete line of material handling equipment including storage silos (bolted and welded), complete railcar unloading systems, complete in-plant distribution systems (both vacuum and pressure), tubing and hardware, and we offer experienced crews for professional installations of any size system.

Standard Features- High & Low level view windows

- Lifting lugs for easy placement in plant

- Bolt-down footpads

- Heavy duty angle iron legs and reinforcement bracing

- Hopper slopes of 45º or 60º

- Hinged top cover for easy access

- Lid configured for mounting PCC vacuum receiver or cyclone

- Exterior painted standard PCC Grey

- Mild steel construction

- Manual or automatically operated slide-gate discharge valve

- Vacuum take-away box with aspirated outlet stubs

- Drain tube for discharging directly into Gaylord boxes, drums, or other type of container

- Leg extensions for Gaylord box clearance

- High and/or low level proximity or rotary sensors

- Hopper slopes of 70º for regrinds or difficult flowing materials

- Epoxy coating on interior

- Custom paint color

- Stainless steel construction

- Hardware