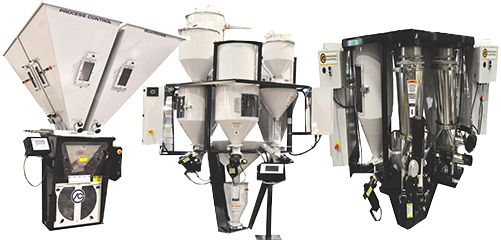

HS-Series Surge Hoppers

Material Handling

The HS Series Surge Hoppers from Process Control are ideal for in-plant storage of both raw materials and finished product. They are available in a variety of sizes and capacities to maximize and conserve handling time, space, and energy. Standard capacities range from 30 cu. ft. to 290 cu. ft. and are available with hopper slopes of 45º or 60º depending on the flow characteristics of the material being stored. Custom designed bins with 70º hopper slopes can also be supplied for regrinds or difficult flowing materials.

The heavy duty design of the HS Series features welded carbon steel construction with formed angle iron legs and reinforcement bracing. The lid of the HS Series is designed for easy mounting of Process Control vacuum receivers or cyclones, and features a hinged cover for easy access. Other standard features include lifting lugs for easy placement of the bin in the plant, bolt down foot pads to securely anchor the bin to the floor, and high and low level view windows for quick visual inspection of the material level within the bin.

Process Control supplies a complete line of material handling equipment including storage silos (bolted and welded), complete railcar unloading systems, complete in-plant distribution systems (both vacuum and pressure), tubing and hardware, and we offer experienced crews for professional installations of any size system.

Standard Features

The heavy duty design of the HS Series features welded carbon steel construction with formed angle iron legs and reinforcement bracing. The lid of the HS Series is designed for easy mounting of Process Control vacuum receivers or cyclones, and features a hinged cover for easy access. Other standard features include lifting lugs for easy placement of the bin in the plant, bolt down foot pads to securely anchor the bin to the floor, and high and low level view windows for quick visual inspection of the material level within the bin.

Process Control supplies a complete line of material handling equipment including storage silos (bolted and welded), complete railcar unloading systems, complete in-plant distribution systems (both vacuum and pressure), tubing and hardware, and we offer experienced crews for professional installations of any size system.

Standard Features

- High & Low level view windows

- Lifting lugs for easy placement in plant

- Bolt-down footpads

- Heavy duty angle iron legs and reinforcement bracing

- Hopper slopes of 45º or 60º

- Hinged top cover for easy access

- Lid configured for mounting PCC vacuum receiver or cyclone

- Exterior painted standard PCC Grey

- Mild steel construction

- Manual or automatically operated slide-gate discharge valve

- Vacuum take-away box with aspirated outlet stubs

- Drain tube for discharging directly into Gaylord boxes, drums, or other type of container

- Leg extensions for Gaylord box clearance

- High and/or low level proximity or rotary sensors

- Hopper slopes of 70º for regrinds or difficult flowing materials

- Epoxy coating on interior

- Custom paint color

- Stainless steel construction

Unit of Measure

| Items |

/Asset/MHS_HS-Series-Surge-Hoppers.jpg /Asset/MHS_HS-Series-Surge-Hoppers.jpg HS01A 45 Degree HS-Series Surge Hopper |

/Asset/MHS_HS-Series-Surge-Hoppers.jpg /Asset/MHS_HS-Series-Surge-Hoppers.jpg HS02A 45 Degree HS-Series Surge Hopper |

/Asset/MHS_HS-Series-Surge-Hoppers.jpg /Asset/MHS_HS-Series-Surge-Hoppers.jpg HS03A 45 Degree HS-Series Surge Hopper |

/Asset/MHS_HS-Series-Surge-Hoppers.jpg /Asset/MHS_HS-Series-Surge-Hoppers.jpg HS05A 45 Degree HS-Series Surge Hopper |

/Asset/MHS_HS-Series-Surge-Hoppers.jpg /Asset/MHS_HS-Series-Surge-Hoppers.jpg HS10A 45 Degree HS-Series Surge Hopper |

|||||

| Maximum Air Volume | N/A 30 ft³ | N/A 60 ft³ | N/A 86 ft³ | N/A 145 ft³ | N/A 286 ft³ | |||||

| Maximum Usable Volume | N/A 17 ft³ | N/A 47 ft³ | N/A 69 ft³ | N/A 116 ft³ | N/A 229 ft³ | |||||

| Dimension A | N/A 48.7 in | N/A 48.7 in | N/A 61.0 in | N/A 61.1 in | N/A 76.0 in | |||||

| Dimension B | N/A 32.7 in | N/A 54.6 in | N/A 57.0 in | N/A 87.2 in | N/A 115.3 in | |||||

| Dimension C | N/A 53.0 in | N/A 77.5 in | N/A 80.0 in | N/A 110.1 in | N/A 138.2 in | |||||

| Dimension D | N/A 49.7 in | N/A 49.7 in | N/A 61.7 in | N/A 61.7 in | N/A 73.7 in | |||||

| Dimension E | N/A 43.0 in | N/A 55.0 in | N/A 55.0 in | N/A 55.0 in | N/A 67.0 in | |||||

| Angle | N/A 45 º | |||||||||

| Finish | N/A Epoxy Coating | |||||||||

| Paint Type | N/A Custom | |||||||||

| Material of Construction | N/A Mild Steel Stainless Steel | |||||||||

| Shipping Weight | N/A 450 lb | N/A 575 lb | N/A 850 lb | N/A 1060 lb | N/A 2150 lb | |||||

| Note | N/A Usable volume is based on a 30 degree angle of repose | |||||||||

|

|

||||||||||