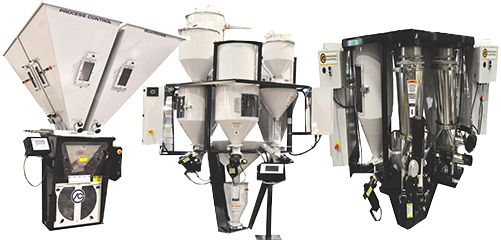

LC-Series Compressed Air Loaders

Material Handling

The LC Series vacuum loader from Process Control is a space efficient, self-contained unit which uses compressed air to convey materials at rates up to 850 PPH. It can be used effectively in any application that calls for raw material delivery.

The LC Series loader is economically priced and comes equipped with all components needed to quickly load raw materials into any processing machine or storage bin. Each unit is shipped fully assembled and tested. The LC Series can be used to load pellets, regrinds, and granular type materials.

The LC Series assembly is comprised of a high efficiency cyclonic hopper mounted on a clear view tube with mounting flange, an air-flow amplifier, an exhaust air filter, and control box. Loading is controlled by a proximity sensor mounted in the view tube. All components are attached directly to the unit, making installation fast and simple. An aspirated pickup wand and 10 ft of PVC flex hose is included for pulling raw material from Gaylord boxes or storage bins.

The direct-mount design of the LC Series is ideal for machine-side loading applications and eliminates the need for bulky, machine-mounted surge hoppers. The LC Series loaders offer continuous, reliable operation with minimal required maintenance. Cleanout is quick, and fast material changes are easily accomplished without wasteful down-time for draining and cleaning common with larger surge hoppers.

Standard Features

The LC Series loader is economically priced and comes equipped with all components needed to quickly load raw materials into any processing machine or storage bin. Each unit is shipped fully assembled and tested. The LC Series can be used to load pellets, regrinds, and granular type materials.

The LC Series assembly is comprised of a high efficiency cyclonic hopper mounted on a clear view tube with mounting flange, an air-flow amplifier, an exhaust air filter, and control box. Loading is controlled by a proximity sensor mounted in the view tube. All components are attached directly to the unit, making installation fast and simple. An aspirated pickup wand and 10 ft of PVC flex hose is included for pulling raw material from Gaylord boxes or storage bins.

The direct-mount design of the LC Series is ideal for machine-side loading applications and eliminates the need for bulky, machine-mounted surge hoppers. The LC Series loaders offer continuous, reliable operation with minimal required maintenance. Cleanout is quick, and fast material changes are easily accomplished without wasteful down-time for draining and cleaning common with larger surge hoppers.

Standard Features

- Clear view material outlet tube

- Mounting flange

- Easily accessible, top-mounted air discharge filter

- Load level proximity sensor

- Aspirated pickup wand and 10 ft of PVC flex hose

- Air operated venturi requires 80 - 100 psi plant compressed air. Total supply air required varies based on model and throughput.

- Power: 115V/1PH/60Hz or 230V/1PH/50Hz

- Mild steel construction

- Custom mounting adapter

- Stainless steel construction

- Dual inlet for proportional loading of pellets and regrinds. Brings both material in simultaneously to eliminate layering. The percentages are set by adjusting the air pressure settings.

Unit of Measure

| Items |

/Asset/Untitled-8.jpg /Asset/Untitled-8.jpg LCA LC-Series Compressed Air Loaders |

/Asset/Untitled-8.jpg /Asset/Untitled-8.jpg LCB LC-Series Compressed Air Loaders |

/Asset/Untitled-8.jpg /Asset/Untitled-8.jpg LCC LC-Series Compressed Air Loaders |

/Asset/Untitled-8.jpg /Asset/Untitled-8.jpg LCD LC-Series Compressed Air Loaders |

||||

| Nominal Rate1 | N/A 130 PPH60 kg/h | N/A 350 PPH160 kg/h | N/A 600 PPH275 kg/h | N/A 850 PPH385 kg/h | ||||

| Maximum Air Consumption @ 80 psig2 | N/A 15 cfm | N/A 15 cfm | N/A 25 cfm | N/A 33 cfm | ||||

| Dimension A | N/A 11.08 in281 mm | N/A 11.08 in281 mm | N/A 16.20 in411 mm | N/A 20.94 in532 mm | ||||

| Dimension B | N/A 6.0 in152 mm | N/A 6.0 in152 mm | N/A 10.43 in265 mm | N/A 14.81 in376 mm | ||||

| Dimension C | N/A 6.63 in168 mm | N/A 6.63 in168 mm | N/A 9.38 in239 mm | N/A 11.38 in289 mm | ||||

| Dimension D | N/A 0.75 in19 mm | N/A 1.0 in25 mm | N/A 1.25 in32 mm | N/A 1.50 in38 mm | ||||

| Dimension E | N/A 12.59 in320 mm | N/A 12.59 in320 mm | N/A 12.64 in321 mm | N/A 15.64 in397 mm | ||||

| Dimension F | N/A 6.28 in160 mm | N/A 6.28 in160 mm | N/A 9.87 in251 mm | N/A 12.63 in321 mm | ||||

| Voltage | N/A 115 V230 V | |||||||

| Phase | N/A Single | |||||||

| Frequency | N/A 50 Hz60 Hz | |||||||

| Material of Construction | N/A Mild Steel Stainless Steel | |||||||

| Shipping Weight | N/A 15 lb6.8 kg | N/A 15 lb6.8 kg | N/A 22 lb10 kg | N/A 30 lb13.6 kg | ||||

| Note | N/A Rates can vary based on material and conveying distance. | |||||||

|

||||||||