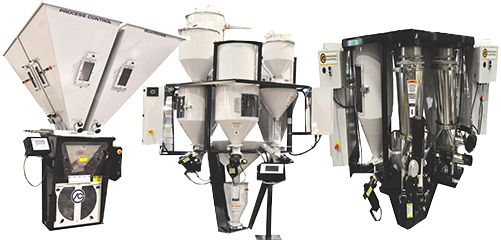

RP-Series Vacuum Receiver for Dusty Material

Material Handling

The RP Series Vacuum Receiver from Process Control is part of a complete vacuum conveying system for in-plant distribution or machine/blender loading. When coupled with a vacuum pump and sequencing panel, the RP Series provides automatic loading of materials.

The RP's design accomplishes cleaning with conveying air. No plant compressed air is used for cleaning. The receiver's self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. At the start of the cycle, air is drawn backward through one set of filter bags, dislodging any fines and dropping them back into the hopper. After filling, the second set of filters is back flushed. Finally, both filters are opened; the resin is delivered to its destination.

The RP Series avoids carry-over of dust back to the vacuum power unit. The filter bags in the RP Series feature large filter areas to promote low, stable pressure drop.

The RP Series Vacuum Receiver is low-maintenance. No valves come into contact with conveyed material and no tools are needed for filter cleaning or changes.

Multiple station capability is engineered into the RP Series design, allowing use of vacuum valves. PCC's RP Series is easily retrofitted to conform to your existing standard vacuum system. An optional modular control box operates valves from the existing sequencing fill signal to minimize field wiring.

Standard Features

The RP's design accomplishes cleaning with conveying air. No plant compressed air is used for cleaning. The receiver's self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. At the start of the cycle, air is drawn backward through one set of filter bags, dislodging any fines and dropping them back into the hopper. After filling, the second set of filters is back flushed. Finally, both filters are opened; the resin is delivered to its destination.

The RP Series avoids carry-over of dust back to the vacuum power unit. The filter bags in the RP Series feature large filter areas to promote low, stable pressure drop.

The RP Series Vacuum Receiver is low-maintenance. No valves come into contact with conveyed material and no tools are needed for filter cleaning or changes.

Multiple station capability is engineered into the RP Series design, allowing use of vacuum valves. PCC's RP Series is easily retrofitted to conform to your existing standard vacuum system. An optional modular control box operates valves from the existing sequencing fill signal to minimize field wiring.

Standard Features

- Air operated sequencing valve in lid requires 80-100 psi of filtered, lubricated shop air for solenoid actuators and control cylinders. The total supply air required per cycle is 0.01 cu. ft.

- Internal self-cleaning filter bags for granular or dusty materials

- 24 VDC control voltage

- Flapper-type discharge valve with magnetic switch

- Removable lid with V-band clamp

- Mild steel construction

- Check valve for common material line applications

- Swing-gate or knife-gate positive shut-off discharge valve

- 110VAC control voltage

- Stainless steel construction

- Load level proximity switch

- Pre-wired junction box to simplify installation

- High temperature design

Unit of Measure

| Items |

/Asset/MHS_RP-Series-Vacuum-Receiver.jpg /Asset/MHS_RP-Series-Vacuum-Receiver.jpg RPFF RP Series Vacuum Receiver for Dusty Material with Flapper Valve Discharge |

/Asset/MHS_RP-Series-Vacuum-Receiver.jpg /Asset/MHS_RP-Series-Vacuum-Receiver.jpg RPGF RP Series Vacuum Receiver for Dusty Material with Flapper Valve Discharge |

/Asset/MHS_RP-Series-Vacuum-Receiver.jpg /Asset/MHS_RP-Series-Vacuum-Receiver.jpg RPHF RP Series Vacuum Receiver for Dusty Material with Flapper Valve Discharge |

/Asset/MHS_RP-Series-Vacuum-Receiver.jpg /Asset/MHS_RP-Series-Vacuum-Receiver.jpg RPJF RP Series Vacuum Receiver for Dusty Material with Flapper Valve Discharge |

/Asset/MHS_RP-Series-Vacuum-Receiver.jpg /Asset/MHS_RP-Series-Vacuum-Receiver.jpg RPKF RP Series Vacuum Receiver for Dusty Material with Flapper Valve Discharge |

|||||

| Working Capacity | N/A 0.4 ft³11.3 dm³ | N/A 0.54 ft³15.3 dm³ | N/A 0.88 ft³24.9 dm³ | N/A 1.44 ft³40.8 dm³ | N/A 2.58 ft³73.0 dm³ | |||||

| Dimension A | N/A 2.5 in63 mm | N/A 4.19 in106 mm | N/A 2.88 in73 mm | N/A 7.63 in194 mm | N/A 17.5 in445 mm | |||||

| Dimension B | N/A 2.0 in2.5 in3.0 in3.5 in51 mm64 mm76 mm89 mm | N/A 2.0 in2.5 in3.0 in3.5 in51 mm64 mm76 mm89 mm | N/A 2.0 in2.5 in3.0 in3.5 in4.0 in51 mm64 mm76 mm89 mm102 mm | N/A 2.0 in2.5 in3.0 in3.5 in4.0 in51 mm64 mm76 mm89 mm102 mm | N/A 1.5 in2.0 in2.5 in3.0 in3.5 in4.0 in38 mm51 mm64 mm76 mm89 mm102 mm | |||||

| Dimension C | N/A 19.9 in505 mm | N/A 19.9 in505 mm | N/A 24.0 in608 mm | N/A 24.0 in608 mm | N/A 39.0 in989 mm | |||||

| Dimension D | N/A 40.5 in1028 mm | N/A 40.5 in1028 mm | N/A 50.7 in1287 mm | N/A 50.7 in1287 mm | N/A 63.8 in1620 mm | |||||

| Dimension E | N/A 42.5 in1079 mm | N/A 42.5 in1079 mm | N/A 52.7 in1337 mm | N/A 52.7 in1337 mm | N/A 65.8 in1671 mm | |||||

| Dimension F | N/A 3.3 in85 mm | N/A 3.3 in85 mm | N/A 8.2 in208 mm | N/A 8.2 in208 mm | N/A 8.2 in208 mm | |||||

| Dimension G (Diameter) | N/A 12.0 in305 mm | N/A 12.0 in305 mm | N/A 16.0 in406 mm | N/A 16.0 in406 mm | N/A 16.0 in406 mm | |||||

| Dimension H | N/A 15.6 in395 mm | N/A 15.6 in395 mm | N/A 17.6 in446 mm | N/A 17.6 in446 mm | N/A 17.6 in446 mm | |||||

| Control Voltage (DC) | N/A 24 V | |||||||||

| Control Voltage (AC) | N/A 110 V | |||||||||

| Material of Construction | N/A Mild Steel Stainless Steel | |||||||||

| Shipping Weight | N/A 150 lb68 kg | N/A 150 lb68 kg | N/A 200 lb91 kg | N/A 200 lb91 kg | N/A 250 lb114 kg | |||||

|

|

||||||||||