The operational design of the RD Dust Collector works to efficiently remove any fines acquired during a fill cycle. Its cleaning system is operated by the Sequencing Controller to properly back flush the bags. After ten consecutive receivers have filled, the RD automatically takes time out to clean filters. Cleaning also occurs at the end of any loading fill cycle. Various filter bags are available for anything from coarse to extremely fine dust. The filter bags can be easily replaced or cleaned as needed. Once the back flush cleaning system is done, dust is dropped into a bucket for easy removal.

The self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. Step 1 at the beginning of the loading cycle, the valve controlling filter area #1 is open to the atmosphere while a vacuum is drawn on filter area #2. This causes air to be drawn backward through filter area #1, dislodging any accumulated fines and dropping them back into the receiver hopper. After this short back flush phase, the second filter area is back flushed by opening it to the atmosphere while the vacuum continues to be drawn on the first filter area (Step 2). Finally, both filter areas are open to atmosphere and the dust is delivered to the bucket (Step 3).

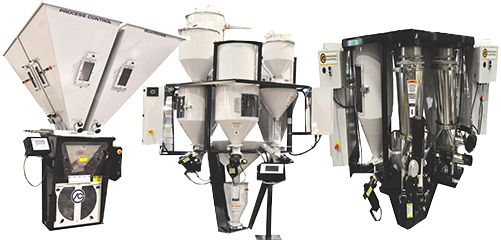

As part of Process Control's Material Handling System, the RD Dust Collector is the ideal solution for dust removal on the vacuum line of a system. With the timed self-cleaning, it keeps the line free of any possible fines associated with pellets or regrind material with minimal operator intervention

Standard Features

The self-cleaning action is achieved by controlled timing of the sequencing vacuum valves. Step 1 at the beginning of the loading cycle, the valve controlling filter area #1 is open to the atmosphere while a vacuum is drawn on filter area #2. This causes air to be drawn backward through filter area #1, dislodging any accumulated fines and dropping them back into the receiver hopper. After this short back flush phase, the second filter area is back flushed by opening it to the atmosphere while the vacuum continues to be drawn on the first filter area (Step 2). Finally, both filter areas are open to atmosphere and the dust is delivered to the bucket (Step 3).

As part of Process Control's Material Handling System, the RD Dust Collector is the ideal solution for dust removal on the vacuum line of a system. With the timed self-cleaning, it keeps the line free of any possible fines associated with pellets or regrind material with minimal operator intervention

Standard Features

- Filter bags

- V Band Clamp

- Dual Solenoid Sequencing T (performs cleaning)

- Flapper Valve Material exit

- Built-in Stand

- Easily removable bucket for dust collection

- AC or DC solenoids

Unit of Measure