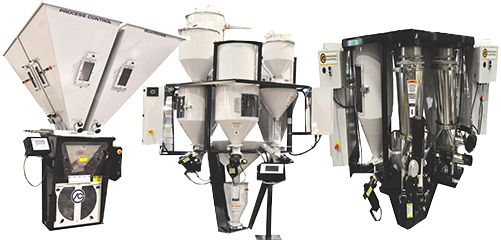

Process Control's material handling equipment is specially designed for bulk conveying of plastic materials. Years of experience with plastic processors enable Process Control engineers to properly size conveying equipment for reliable, cost-effective loading of gravimetric or bulk systems. A complete line of equipment is available including pumps, receivers, controllers, bulk storage silos, day bins and hardware necessary for railcar unloading and integrated plant distribution systems. Compact, simple systems are available for lower throughput applications.

The VF Series is our most popular line of vacuum power units, offering dependable and economical performance for a wide variety of conveying rates, distances and materials. Typical applications include in-plant distribution systems and machine/blender loading. Each system is carefully sized using PCC's computer calculations to meet your conveying specifications.

Standard Features

- 3 to 30 horsepower available

- Positive displacement blower

- Enclosed, V-belt drive

- Single element paper filter assembly

- T-frame TEFC motor (indoor or outdoor)

- Discharge silencer

- Vacuum relief valve and gauge

- Motor starter panel

Options

- Variable Speed Drive controlled

- Special voltages

- Continuous run valve to reduce pump cycling

- Sound-deadening enclosures

- Outdoor construction

The VF Series: designed for conveying of plastic materials (Both sound enclosed and non sound enclosed models)