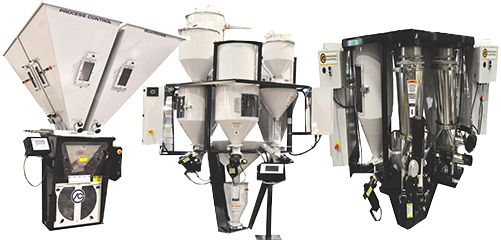

CH-Series Transfer Stations

Railcar Unloading

Process Control Corporation specializes in equipment for bulk conveying of plastic materials. The equipment is designed to stand up to the toughest demands of your application, including high material flow rates, multiple distribution points and long conveying distances.

The CH Series transfer station, with cyclone, is designed for use in dual blower conveying systems. Used in conjunction with the VL Series vacuum pump and P series pressure pump (both available separately), the CH Series is used to transfer the material from the vacuum part of the system to the pressure part of the system. The VL pump creates the vacuum which pulls the material from a railcar or truck into the cyclone mounted on top of the transfer station. The material then drops down, through a rotary airlock feeder, into a blow through assembly. The P series then applies the pressure to convey the material to its storage point, silo or day bin. Process Control engineers are always available to assist you in designing the best system to meet your application. Process Control supplies a complete line of material handling equipment including tubing and hardware, vacuum and pressure pumps, controllers, silos and day bins.

Standard Features

The CH Series transfer station, with cyclone, is designed for use in dual blower conveying systems. Used in conjunction with the VL Series vacuum pump and P series pressure pump (both available separately), the CH Series is used to transfer the material from the vacuum part of the system to the pressure part of the system. The VL pump creates the vacuum which pulls the material from a railcar or truck into the cyclone mounted on top of the transfer station. The material then drops down, through a rotary airlock feeder, into a blow through assembly. The P series then applies the pressure to convey the material to its storage point, silo or day bin. Process Control engineers are always available to assist you in designing the best system to meet your application. Process Control supplies a complete line of material handling equipment including tubing and hardware, vacuum and pressure pumps, controllers, silos and day bins.

Standard Features

- Rotary feeder with shear eliminator and vent

- Polyphase gear motor Power: 460V/3Ph/60Hz

- High efficiency cyclone designed for air flow as required

- Level control rotary vane, electromechanical type

- Four-sided chain guard w/removable access cover

- Reinforced heavy steel base plate

- Mild steel construction

- Special motor

- Special electricals

- Epoxy coating

- Stainless steel construction

- Special paint

- Baghouse type filter

Unit of Measure

| Items |

/Asset/MHS_CH-Series-Transfer-Station.jpg /Asset/MHS_CH-Series-Transfer-Station.jpg CH25_825_ CH-Series Transfer Stations |

/Asset/MHS_CH-Series-Transfer-Station.jpg /Asset/MHS_CH-Series-Transfer-Station.jpg CH30_1025_ CH-Series Transfer Stations |

/Asset/MHS_CH-Series-Transfer-Station.jpg /Asset/MHS_CH-Series-Transfer-Station.jpg CH35_1030_ CH-Series Transfer Stations |

/Asset/MHS_CH-Series-Transfer-Station.jpg /Asset/MHS_CH-Series-Transfer-Station.jpg CH40_1235_ CH-Series Transfer Stations |

/Asset/MHS_CH-Series-Transfer-Station.jpg /Asset/MHS_CH-Series-Transfer-Station.jpg CH45_1240_ CH-Series Transfer Stations |

|||||

| Rotary Feeder | N/A 0.75 hp | N/A 1.0 hp | N/A 1.0 hp | N/A 1.5 hp | N/A 1.5 hp | |||||

| Dimension A | N/A 2.5 in64 mm | N/A 3.0 in76 mm | N/A 3.5 in89 mm | N/A 4.0 in102 mm | N/A 4.5 in114 mm | |||||

| Dimension B | N/A 2.5 in64 mm | N/A 3.0 in76 mm | N/A 3.5 in89 mm | N/A 4.0 in102 mm | N/A 4.5 in114 mm | |||||

| Dimension C | N/A 2.5 in64 mm | N/A 2.5 in64 mm | N/A 3.0 in76 mm | N/A 3.5 in89 mm | N/A 4.0 in102 mm | |||||

| Dimension D | N/A 45.5 in1149 mm | N/A 48.25 in1226 mm | N/A 48.25 in1226 mm | N/A 49.75 in1264 mm | N/A 49.75 in1264 mm | |||||

| Dimension E | N/A 23.0 in584 mm | N/A 26.5 in673 mm | N/A 26.5 in673 mm | N/A 30.5 in774 mm | N/A 30.5 in774 mm | |||||

| Dimension F | N/A 115.0 in2921 mm | N/A 123.0 in3124 mm | N/A 123.25 in3131 mm | N/A 131.0 in3327 mm | N/A 132.25 in3359 mm | |||||

| Dimension G | N/A 9.41 in239 mm | |||||||||

| Dimension H | N/A 113.75 in2889 mm | N/A 119.97 in3047 mm | N/A 121.74 in3092 mm | N/A 112.36 in2854 mm | N/A 103.34 in2625 mm | |||||

| Dimension J | N/A 103.5 in2629 mm | N/A 111.3 in2827 mm | N/A 112.72 in2863 mm | N/A 126.65 in3217 mm | N/A 112.6 in2860 mm | |||||

| Paint Type | N/A Special | |||||||||

| Finish | N/A Epoxy Coating | |||||||||

| Base Plate Material | N/A Reinforced Heavy Steel | |||||||||

| Material of Construction | N/A Mild Steel | |||||||||

| Shipping Weight | N/A 1217 lb553 kg | N/A 1626 lb739 kg | N/A 1639 lb745 kg | N/A 1826 lb830 kg | N/A 1837 lb835 kg | |||||

| Voltage | N/A 460 V | |||||||||

| Phase | N/A Three | |||||||||

| Frequency | N/A 60 Hz | |||||||||

|

|

||||||||||