P-Series Pressure Power Units

Railcar Unloading

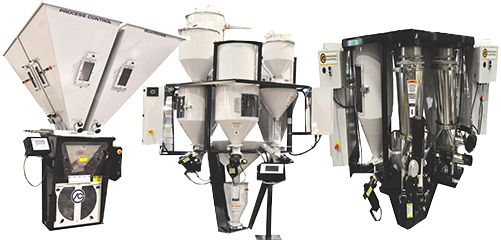

Process Control Corporation specializes in equipment for conveying plastic materials. Our equipment is designed to stand up to the toughest demands of your application, including high material flow rates, multiple distribution points and long conveying distances.

To prevent bottle necking and ensure a continuous supply of material to any number of plant sites (silos, surge bins, processing machines, blenders, etc.), Process Control engineers work with you to select the best equipment and integrate it into a reliable system capable of continuous operation and guaranteed performance.

Our P Series Pressure Power Unit is designed for quiet, reliable performance in a pressure conveying system or as part of a dual-blower vacuum/ pressure system. Typical applications include railcar/ truck unloading and in-plant distribution systems. Eleven standard P Series units are available, with horsepower ratings from two to fifty.

Process Control supplies a complete line of material handling equipment including tubing and hardware, vacuum pumps, controllers, bolted & welded storage silos and day bins.

Standard Features

To prevent bottle necking and ensure a continuous supply of material to any number of plant sites (silos, surge bins, processing machines, blenders, etc.), Process Control engineers work with you to select the best equipment and integrate it into a reliable system capable of continuous operation and guaranteed performance.

Our P Series Pressure Power Unit is designed for quiet, reliable performance in a pressure conveying system or as part of a dual-blower vacuum/ pressure system. Typical applications include railcar/ truck unloading and in-plant distribution systems. Eleven standard P Series units are available, with horsepower ratings from two to fifty.

Process Control supplies a complete line of material handling equipment including tubing and hardware, vacuum pumps, controllers, bolted & welded storage silos and day bins.

Standard Features

- 2 to 50 horsepower available

- Positive displacement blower

- T-frame motor

- Intake- and pressure-side silencer

- Reinforced, heavy steel base plate

- NEMA-12 electrical/control enclosure

- Cartridge type, intake-side air filter

- Adjustable pressure switch with diaphragm-piston transducer

- Four-sided belt guard with removable access cover

- Special motor

- Level controls at storage or use point

- Special electricals

- Special paint

- Heat exchanger for cooling conveying air.

Unit of Measure

| Items |

/Asset/MHS_P-Series-Pressure-Power-Unit.jpg /Asset/MHS_P-Series-Pressure-Power-Unit.jpg P0220 P-Series Pressure Power Units |

/Asset/MHS_P-Series-Pressure-Power-Unit.jpg /Asset/MHS_P-Series-Pressure-Power-Unit.jpg P0320 P-Series Pressure Power Units |

/Asset/MHS_P-Series-Pressure-Power-Unit.jpg /Asset/MHS_P-Series-Pressure-Power-Unit.jpg P0525 P-Series Pressure Power Units |

/Asset/MHS_P-Series-Pressure-Power-Unit.jpg /Asset/MHS_P-Series-Pressure-Power-Unit.jpg P0725 P-Series Pressure Power Units |

/Asset/MHS_P-Series-Pressure-Power-Unit.jpg /Asset/MHS_P-Series-Pressure-Power-Unit.jpg P1025 P-Series Pressure Power Units |

|||||

| Motor Power | N/A 2 hp1.5 kW | N/A 3 hp2.25 kW | N/A 5 hp3.75 kW | N/A 7.5 hp5.6 kW | N/A 10 hp7.5 kW | |||||

| Dimension A | N/A 2.0 in51 mm | N/A 2.0 in51 mm | N/A 2.5 in64 mm | N/A 2.5 in64 mm | N/A 2.5 in64 mm | |||||

| Dimension B | N/A 57.5 in1461 mm | N/A 55.0 in1397 mm | N/A 75.0 in1905 mm | N/A 72.8 in1850 mm | N/A 72.8 in1850 mm | |||||

| Dimension C | N/A 16.0 in408 mm | N/A 20.0 in508 mm | N/A 20.0 in508 mm | N/A 21.0 in533 mm | N/A 21.0 in533 mm | |||||

| Dimension D | N/A 34.4 in874 mm | N/A 38.0 in965 mm | N/A 38.0 in965 mm | N/A 36.6 in930 mm | N/A 36.6 in930 mm | |||||

| Paint Type | N/A Special | |||||||||

| Motor Power Ratings | N/A 2 to 50 hp | |||||||||

| Base Plate Material | N/A Reinforced Heavy Steel | |||||||||

| Shipping Weight | N/A 450 lb204 kg | N/A 475 lb216 kg | N/A 575 lb261 kg | N/A 625 lb284 kg | N/A 800 lb363 kg | |||||

|

|

||||||||||