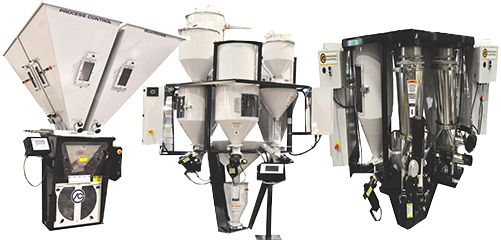

The Guardian® Series 2 gravimetric batch blender was developed for processors who want the simplicity of operation combined with the most accurate dispensing and superior blend homogeneity at a low cost. For these customers, Process Control designed the Guardian® Series 2. The blenders in the 25kg Guardian® Series 2 family have been made with redesigned material hoppers to hold each of the ingredients. The 25kg can be supplied with up to twelve separate ingredient hoppers as standard.

Both of the designs come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%.

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features

Both of the designs come equipped with a fast acting V-gate valve for the material hoppers. Each of the materials are dispensed sequentially into a common weighing hopper in the desired proportions. The weighed materials are then released into a separate mixing chamber which provides the most consistent homogeneous blend of any batch type blender. Process Control engineers have developed a highly advanced dispensing and weighing system that accurately controls each ingredient of every batch to the desired amounts and is not averaged over multiple batches as is common in other batch blenders in the industry. At the blender’s highest setting, each ingredient can be dispensed to an accuracy of +/- 0.02%.

In addition to precise batch-to-batch dispensing, the performance of the mixer is just as critical to the end product. The mixer actually determines how uniform the blend will be. Inadequate mixing can lead to inconsistent product characteristics such as color variations or other imperfections. The Guardian® Series 2 blenders have incorporated a built in clean-out system in the design. With a pull-out drain chute and separate manual slide-gate controls, the blender can be cleaned out quickly and easily during product changeovers.

Standard Features

- • Each hopper has one 90° side and no transition sections for improved material flow.

- • Hopper access doors with redesigned latching system.

- • Detached weigh hopper discharge gate actuator for improved performance.

- • Removable cartridge style dispensing gates for ease of maintenance and clean out.

- • Optimized V-design metering gates for improved accuracy and dispensing range.

- • Color touch screen operator interface with new “off-the-shelf” control.

- • PCC Web® remote communication software

- • Gravitrol® extruder and linespeed control

- • Extension cable kit for remote mounting touch-screen operator control panel

- • Low level proximity sensors for material hoppers

- • Special electrical

- • Special Paint

- • Blend Manager software

- • Self-Loading

- • Self-Cleaning

- • Up to 12 elements for 18kg and 25kg

- • For higher throughputs, see specification sheets for 1.25kg & 2.5kg, 5kg, and 12kg Guardian® Series 2 Gravimetric Blenders

Unit of Measure

- 1 Depending on Materials & Accuracy Setting

- 2 Depending on Materials & Accuracy Setting

- 3 Depending on Materials & Accuracy Setting