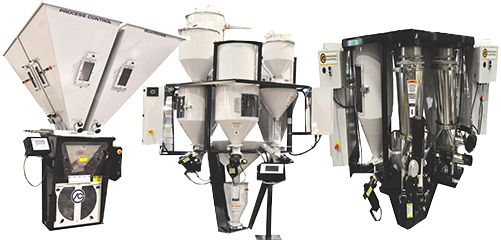

AFV-Series Precision Additive Feeders

Additive Feeders

The AFV Series Volumetric Additive Material Feeder from Process Control is designed to inject color concentrates or other additive-type materials directly into a material stream at the feed throat of an Extruder or molding machine. The AFV Series is a simple, easy to operate feeder, offering unparalleled accuracy and cost savings to plastic processors.

Standard features include a horizontal solid-flight auger with a 1/4 HP variable speed AC gearmotor for precise metering of colorants or other additives into the virgin or virgin/regrind flow as it enters the machine throat. The digital controller can be configured for local manual speed control or can be synchronized to either follow an Extruder rate or run in a remote run/stop mode for injection molding processes. Other standard features include a sample port for feeder calibration, a clear view sight glass on either side, and a material drain port for easy clean-out and quick material changes. The hopper lid can be configured either for hand loading or with mounting provisions for a vacuum type loader.

The feeders are available in two different hopper sizes and various auger and gear motor ratios for rates of 0.5 - 3,500 PPH. A central mounting adapter can accommodate up to (4) feeders for introducing various colors and/or additives into a single processing machine.

Standard Features

Standard features include a horizontal solid-flight auger with a 1/4 HP variable speed AC gearmotor for precise metering of colorants or other additives into the virgin or virgin/regrind flow as it enters the machine throat. The digital controller can be configured for local manual speed control or can be synchronized to either follow an Extruder rate or run in a remote run/stop mode for injection molding processes. Other standard features include a sample port for feeder calibration, a clear view sight glass on either side, and a material drain port for easy clean-out and quick material changes. The hopper lid can be configured either for hand loading or with mounting provisions for a vacuum type loader.

The feeders are available in two different hopper sizes and various auger and gear motor ratios for rates of 0.5 - 3,500 PPH. A central mounting adapter can accommodate up to (4) feeders for introducing various colors and/or additives into a single processing machine.

Standard Features

- Horizontal solid-flight auger

- 1/4 HP variable speed AC gearmotor

- Sample port

- Push button controller with digital display

- Clear view window on either side

- Material drain port

- Removable lid for hand loading

- Carbon steel construction

- Power Requirements: 115V/1PH/60Hz - (UL)

- Custom mounting adapters

- 1/2 HP gearmotor for difficult-to-flow materials

- Low level proximity sensor for alarm

- Hi-temperature design

- Receiver mount lid for automatic loading

- Stainless steel construction

- Power Requirements: 230V/1PH/50Hz - (CE)

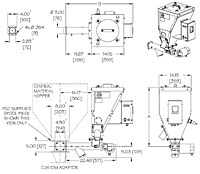

Item # |

Hopper Capacity |

Dimension A |

Dimension B |

Gear Motor Power (AC) |

Shipping Weight |

|---|---|---|---|---|---|

| AFVB AFVB/Asset/MHS_AFV-Series-Precision-Additive-Feeders.jpg | Hopper Capacity N/A 1.0 ft³28.3 dm³ | Dimension A N/A 19.27 in489 mm | Dimension B N/A 31.28 in794 mm | Gear Motor Power (AC) N/A 1/4 hp | Shipping Weight N/A 75 lb34.1 kg |

| AFVC AFVC/Asset/MHS_AFV-Series-Precision-Additive-Feeders.jpg | Hopper Capacity N/A 1.5 ft³42.4 dm³ | Dimension A N/A 26.27 in667 mm | Dimension B N/A 29.92 in760 mm | Gear Motor Power (AC) N/A 1/4 hp | Shipping Weight N/A 100 lb45.5 kg |