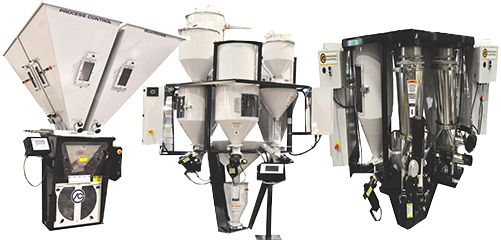

IN-Series Trim Removal Inducers

ASR® - Automatic Scrap Recycling

Process Control's IN Series Inducers are designed to pick up and convey edge and/or bleed trims generated in the production of plastic film or other thin-gauge products such as foam, tape, paper or foil. These continuous trims are picked up by suction, conveyed into the inducer's venturi section and blown to a destination such as a Process Control film grinder or a waste container.

Process Control inducer manifolds are designed to insure that the air velocity at the pickup point is maintained so that trims do not wrap around the cutters.

The IN Series inducers feature an adjustable venturi to allow you to tune the inducer for peak performance with your installation.

IN Series inducers have a higher induced air to primary air ratio than conventional trim removal systems, providing excellent pickup and conveying performance.

IN Series inducers are designed to adapt easily to the installation requirements of your extrusion lines. The unit is shipped with its fan in a top- horizontal arrangement, but can be easily rotated in 90° increments to provide the required fan/venturi orientation. The fan may also be mounted remotely from the venturi using additional tubing.

Standard Features

Process Control inducer manifolds are designed to insure that the air velocity at the pickup point is maintained so that trims do not wrap around the cutters.

The IN Series inducers feature an adjustable venturi to allow you to tune the inducer for peak performance with your installation.

IN Series inducers have a higher induced air to primary air ratio than conventional trim removal systems, providing excellent pickup and conveying performance.

IN Series inducers are designed to adapt easily to the installation requirements of your extrusion lines. The unit is shipped with its fan in a top- horizontal arrangement, but can be easily rotated in 90° increments to provide the required fan/venturi orientation. The fan may also be mounted remotely from the venturi using additional tubing.

Standard Features

- 5 - 20 HP AC, TEFC motors

- Power Requirements: 460/3PH/60Hz

- Electricals: Starter and controls are normally included in a PCC Grinder control panel when purchased as part of a complete asr® (Automatic Scrap Recycling system), or can be supplied in a separate standalone panel.

- Silencer on the fan inlet

- Mild steel construction

- High gloss epoxy paint in PCC standard color

- Interconnecting tubing and hardware

- Venturi inlet bell-mouth

- Edge and/or bleed trim pickup manifolds

- Silencers on the venturi inlet and outlet

- AEN air eliminator to separate conveying air from trims

- Special electricals

- Special paint

Item # |

Motor Power |

Line Speed |

Dimension A |

Dimension B |

Inlet Size |

Outlet Size |

|---|---|---|---|---|---|---|

| IN405 IN405/Asset/ASR_IN-Series-Trim-Removal-Inducers.jpg | Motor Power N/A 5 hp3.7 kW | Line Speed N/A Up to 600 ft/min | Dimension A N/A 44.0 in1115 mm | Dimension B N/A 25.0 in635 mm | Inlet Size N/A 4.0 in102 mm | Outlet Size N/A 6.63 in168 mm |

| IN415 IN415/Asset/ASR_IN-Series-Trim-Removal-Inducers.jpg | Motor Power N/A 15 hp11 kW | Line Speed N/A Up to 1200 ft/min | Dimension A N/A 55.0 in1400 mm | Dimension B N/A 48.0 in1215 mm | Inlet Size N/A 4.0 in102 mm | Outlet Size N/A 8.0 in203 mm |

| IN420 IN420/Asset/ASR_IN-Series-Trim-Removal-Inducers.jpg | Motor Power N/A 20 hp15.0 kW | Line Speed N/A Up to 1500 ft/min | Dimension A N/A 55.0 in1400 mm | Dimension B N/A 48.0 in1215 mm | Inlet Size N/A 4.0 in102 mm | Outlet Size N/A 8.0 in203 mm |