GF-Series Film Scrap Grinders

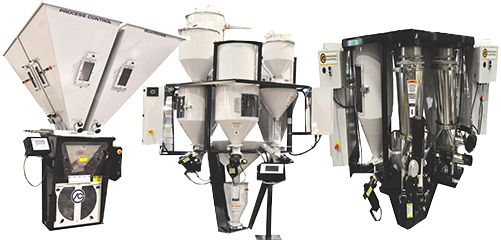

GF Series Film Scrap Grinder & Accessories

The GF Series grinders from Process Control Corporation are used as part of an asr® Automatic Scrap Recycling system for in-line recycling of production film scrap. GF Series grinders are designed to provide efficient, uniform grinding of film scrap. There are four cutting chamber sizes available along with different horsepower motors to accurately match the grinder to the required scrap rate. The GF Series grinders are available in configurations that accept edge and bleed trims, roll scrap, and loose scrap.

Standard carbide-coated knives are employed in the system, increasing the time between sharpening. The rotor knives approach the stationary bed knife, or knives, at a steep angle to ensure a clean scissors-cut. This technique is used for maximum bulk-density and flow of ground scrap. The open rotor design improves airflow for cooling , permitting the highest possible throughput.

After the cutting chamber, material passes through a sizing screen that is chosen specifically for the application and material. The ground scrap is pulled through the grinder screen and carried through the process by the scrap conveying fan standard on each GF Series grinder.

Reintroduction of roll scrap is achieved with the attachment of an optional RN Series roll feeder. The roll feeder has knurled rolls that provide a strong pull on the film, without wrapping. They are available in several sizes with variable speed DC motors that run at 3 - 32 fpm (1 - 10 m/min).

The control panel for the grinders includes a motor starter for the grinder. When purchased as part of a complete asr® system, the control panel includes controls for the inducers and roll feeder, as well.

Standard Features

Standard carbide-coated knives are employed in the system, increasing the time between sharpening. The rotor knives approach the stationary bed knife, or knives, at a steep angle to ensure a clean scissors-cut. This technique is used for maximum bulk-density and flow of ground scrap. The open rotor design improves airflow for cooling , permitting the highest possible throughput.

After the cutting chamber, material passes through a sizing screen that is chosen specifically for the application and material. The ground scrap is pulled through the grinder screen and carried through the process by the scrap conveying fan standard on each GF Series grinder.

Reintroduction of roll scrap is achieved with the attachment of an optional RN Series roll feeder. The roll feeder has knurled rolls that provide a strong pull on the film, without wrapping. They are available in several sizes with variable speed DC motors that run at 3 - 32 fpm (1 - 10 m/min).

The control panel for the grinders includes a motor starter for the grinder. When purchased as part of a complete asr® system, the control panel includes controls for the inducers and roll feeder, as well.

Standard Features

- ODP motor with 4-sided belt guard (TEFC motor on GFB)

- Open rotor cutting chamber with outboard bearings

- 2 HP scrap conveying fan (5 HP on GFD)

- Mild steel construction

- Carbide-coated knives

- Remote-mount control panel

- Electricals: Power requirements 460V/3PH/60Hz

- Special paint

- Special electricals

- Hydraulic lift for opening cutting chamber (not available on GFA or GFB, standard on GFD)

- Sound enclosure

- AEN air eliminator separates conveying air from edge trims

- RF Series roll feeder

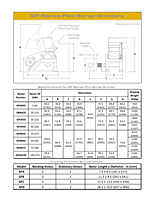

Item # |

Motor Power |

Rotating Knives |

Stationary Knives |

Rotor Length x Rotor Diameter |

Shipping Weight |

|---|---|---|---|---|---|

| GFAN05 GFAN05/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 5 hp4 kW | Rotating Knives N/A 2 | Stationary Knives N/A 1 | Rotor Length x Rotor Diameter N/A 7.5 x 6.2 in191 x 157 mm | Shipping Weight N/A 950 lb432 kg |

| GFBN20 GFBN20/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 20 hp15.0 kW | Rotating Knives N/A 3 | Stationary Knives N/A 1 | Rotor Length x Rotor Diameter N/A 11.5 x 9.5 in292 x 241 mm | Shipping Weight N/A 2500 lb1136 kg |

| GFCN30 GFCN30/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 30 hp22 kW | Rotating Knives N/A 3 | Stationary Knives N/A 1 | Rotor Length x Rotor Diameter N/A 17.5 x 13.2 in445 x 336 mm | Shipping Weight N/A 2600 lb1182 kg |

| GFCN40 GFCN40/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 40 hp30 kW | Rotating Knives N/A 3 | Stationary Knives N/A 1 | Rotor Length x Rotor Diameter N/A 17.5 x 13.2 in445 x 336 mm | Shipping Weight N/A 2655 lb1207 kg |

| GFDN50 GFDN50/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 50 hp37 kW | Rotating Knives N/A 3 | Stationary Knives N/A 2 | Rotor Length x Rotor Diameter N/A 26.5 x 16.0 in637 x 406 mm | Shipping Weight N/A 4025 lb1830 kg |

| GFDN60 GFDN60/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 60 hp45 kW | Rotating Knives N/A 3 | Stationary Knives N/A 2 | Rotor Length x Rotor Diameter N/A 26.5 x 16.0 in637 x 406 mm | Shipping Weight N/A 4190 lb1905 kg |

| GFDN75 GFDN75/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 75 hp56 kW | Rotating Knives N/A 3 | Stationary Knives N/A 2 | Rotor Length x Rotor Diameter N/A 26.5 x 16.0 in637 x 406 mm | Shipping Weight N/A 4190 lb1905 kg |

| GFDN100 GFDN100/Asset/ASR_GF-Series-Film-Scrap-Grinder.jpg | Motor Power N/A 100 hp75 kW | Rotating Knives N/A 3 | Stationary Knives N/A 2 | Rotor Length x Rotor Diameter N/A 26.5 x 16.0 in637 x 406 mm | Shipping Weight N/A 4190 lb1905 kg |